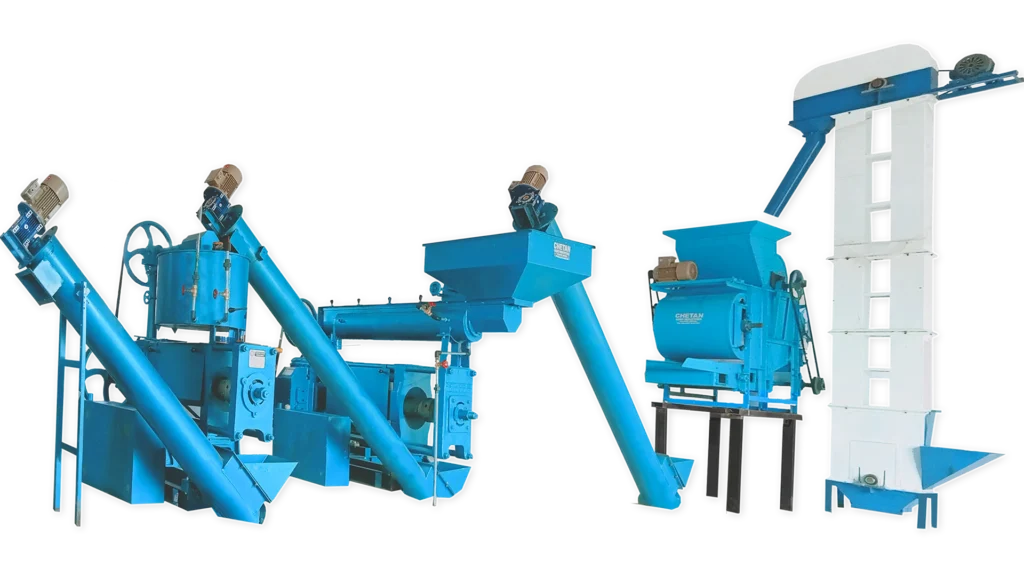

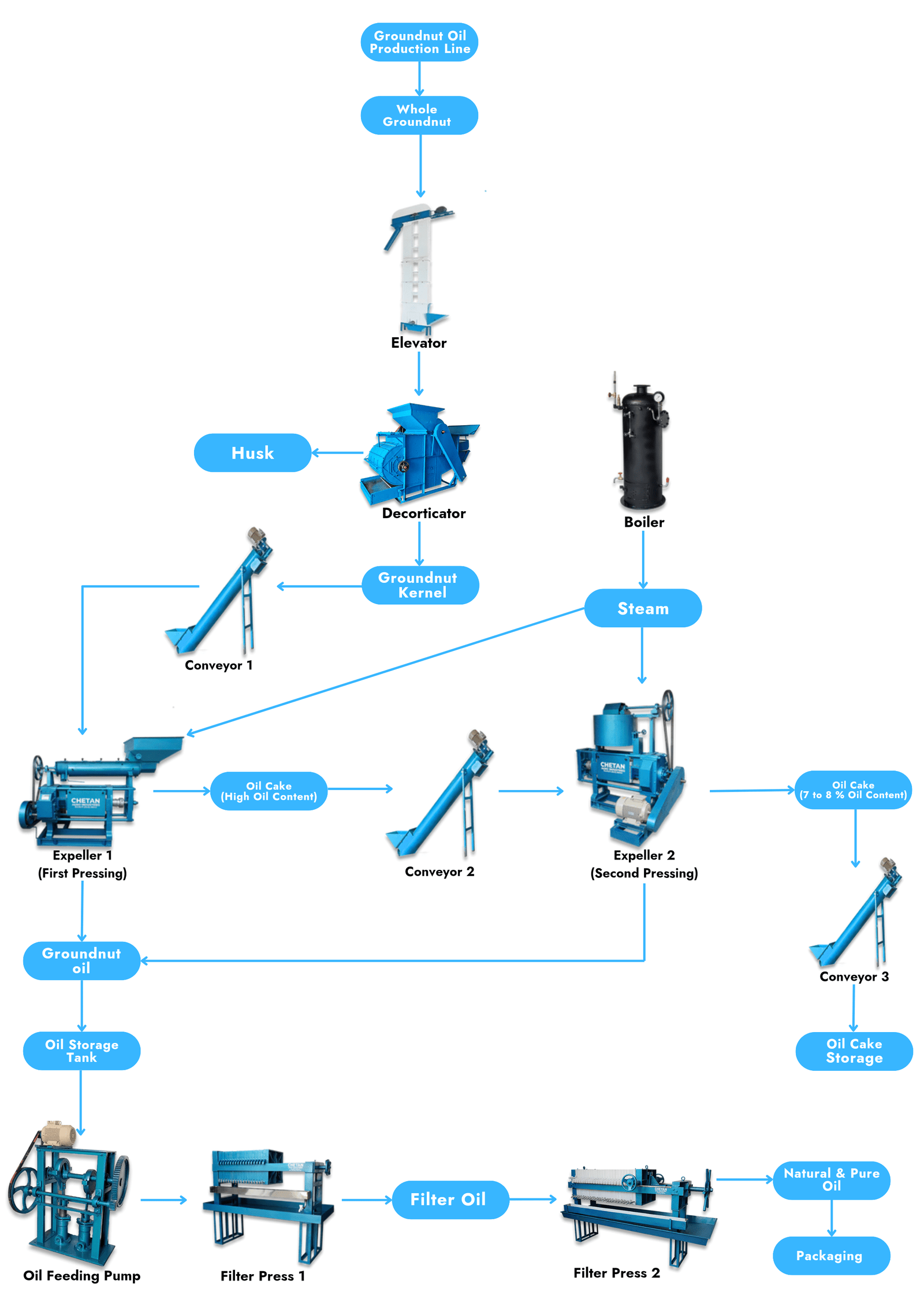

Groundnut Oil Production Line

The Groundnut Oil Production Line begins by cleaning and separating raw groundnuts, using a decorticator to obtain seeds and husks. A screw conveyor then transfers the material to an expeller, which efficiently extracts oil from various seeds. The resulting products include oil cake with 7 to 8% oil content and pure oil. The oil undergoes filtration via an oil feeding pump and filter, yielding a refined product stored in a tank. This streamlined process ensures the production of high-quality groundnut oil for diverse applications

- Whole groundnuts are used as the raw material.

- Groundnuts are placed into the Decorticator via an elevator for Processing.

- Decorticator separates groundnut kernels and husks.

- Boiler produces steam to heat the raw material during the crushing process in the expellers.

- The generated steam aids in facilitating efficient crushing of groundnuts in Expeller

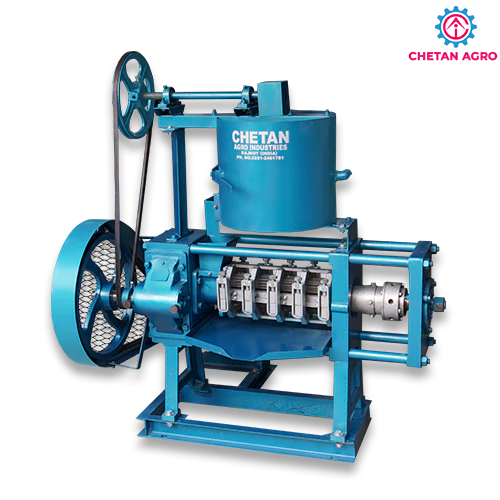

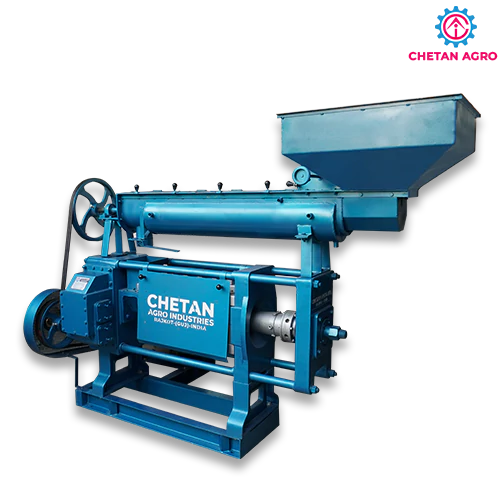

- First Expeller for Crushing groundnuts first time.

- Second Expeller for further crushes groundnuts second time.

- Crushing Output Oil cake with 7-8% oil content.

- Oil Cake Storage for the extracted oil cake.

- Oil Storage Tank for Container storing the extracted oil.

- Oil Feeding Pump facilitates the feeding of oil for filtration.

- First Filtration removes impurities from the oil.

- Second Filtration further refines the oil.

- Final Product Natural and pure groundnut oil.

- after Packaging The oil in tins for distribution.

Groundnut Oil Mill Related Machinery

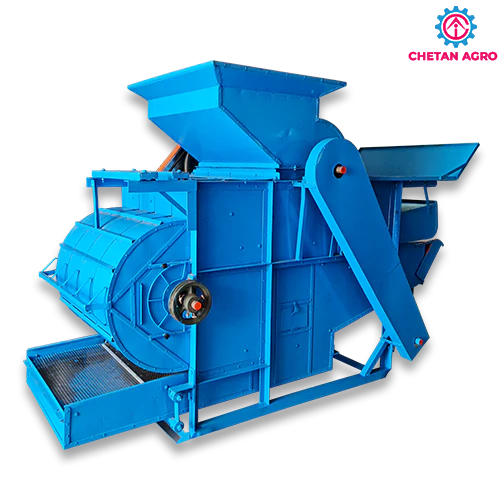

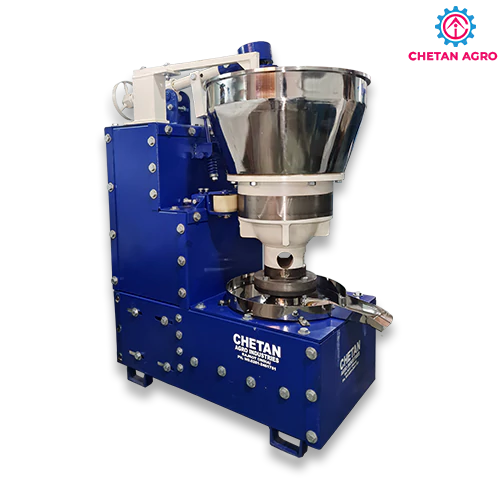

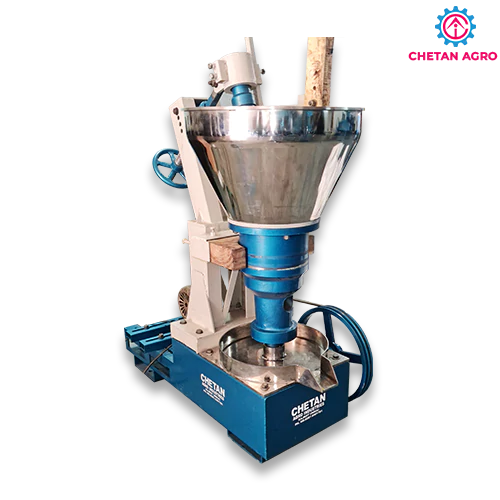

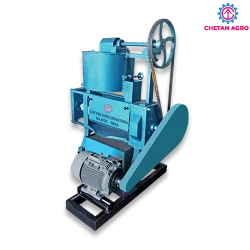

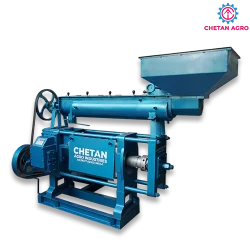

Oil Extraction Machines

6 to 100 TPD Automatic Oil Mill Plant

kg/hr

hp

kg/hr

hp

Mini Oil Mill Plant 2204

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

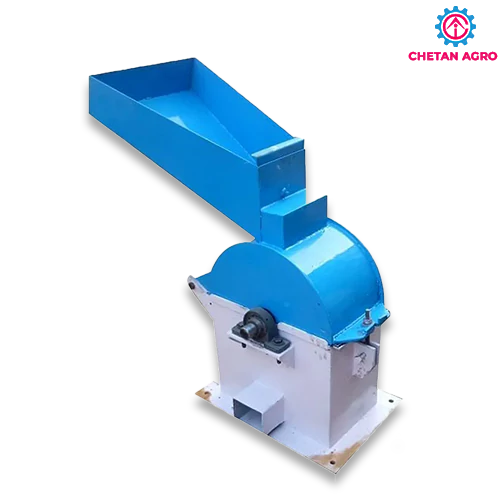

Wooden Oil Press Machine

kg/hr

hp

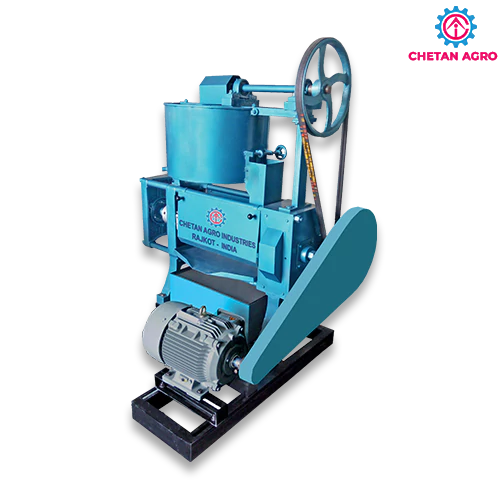

Rotary Oil Ghani Machine

kg/hr

hp

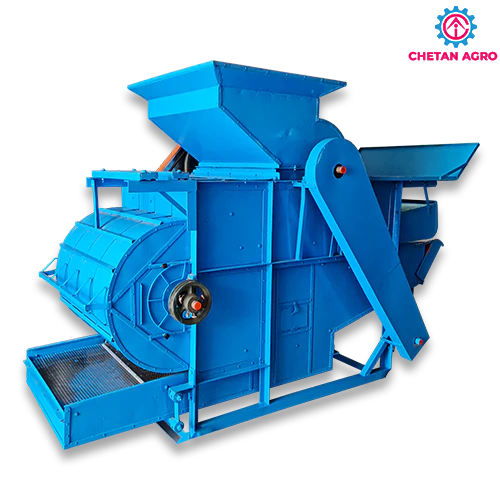

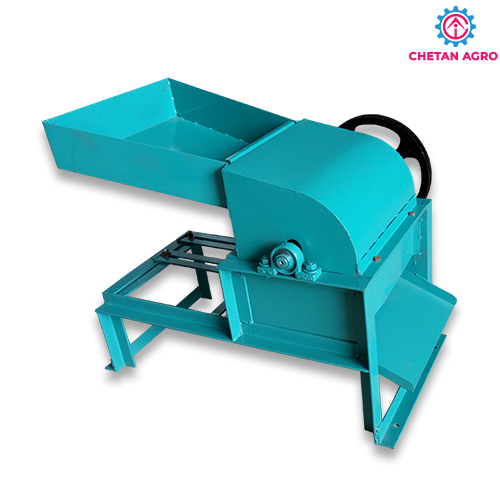

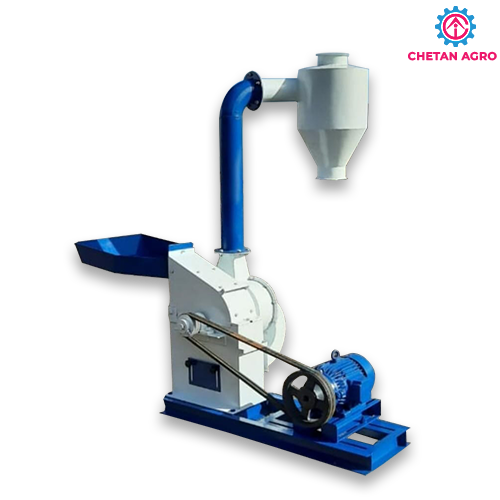

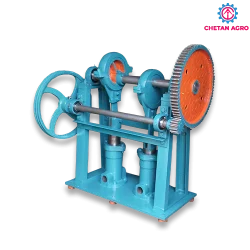

Decorticator Machine, Seed Cleaning and Grading

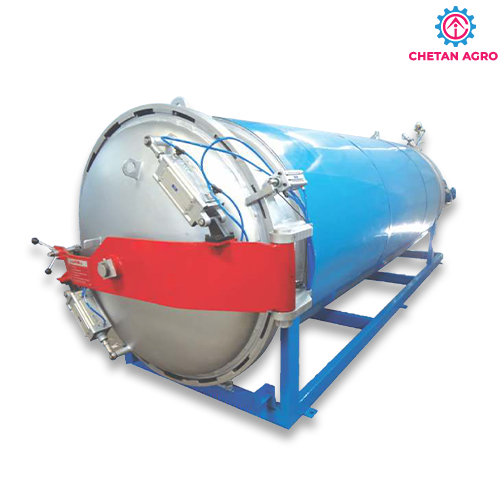

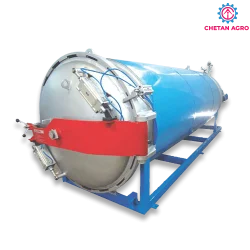

Wood Fire Boiler

kg/hr

hp

kg/hr

hp

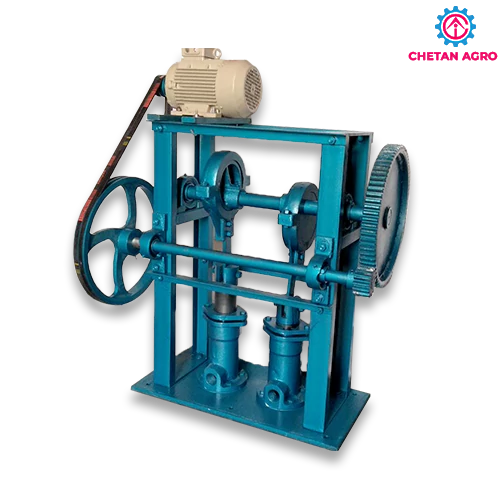

Electric Boiler

kg/hr

kw

ton/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

Decorticator DM

kg/hr

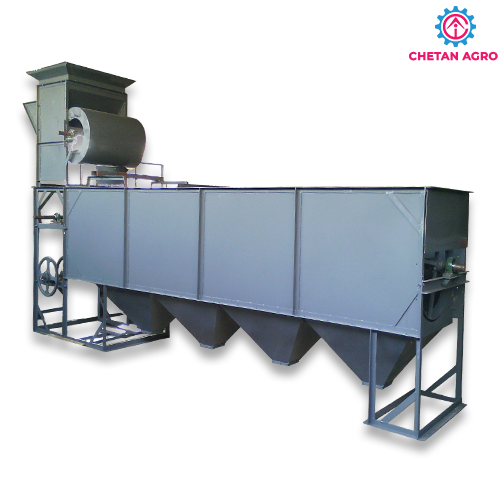

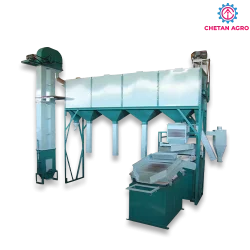

Seed Conditioner (Copra Dryer, Cooker)

kg/hr

hp

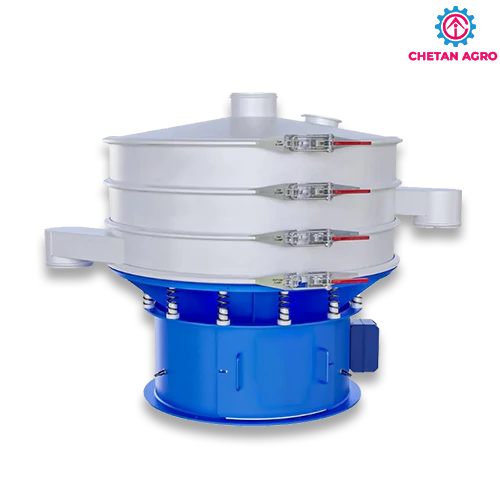

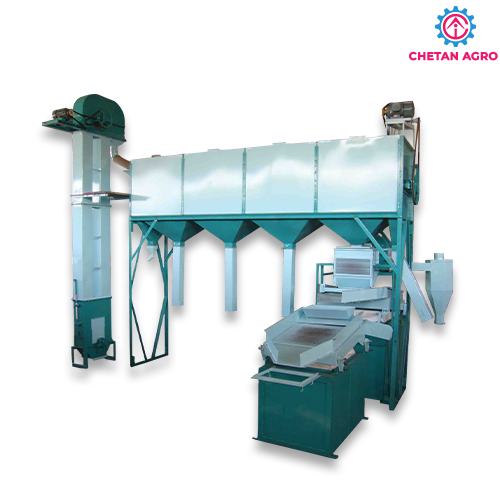

Seed Cleaning Plant

kg/hr

hp

kg/hr

hp

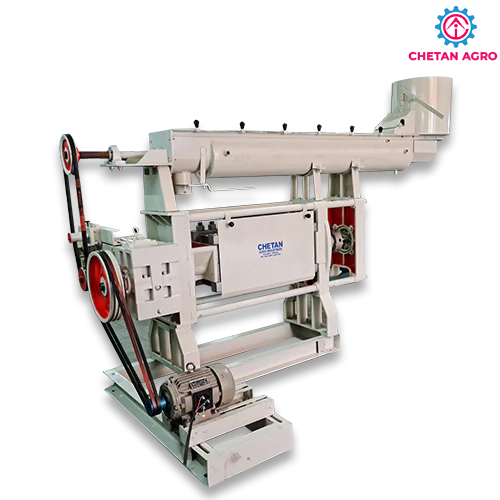

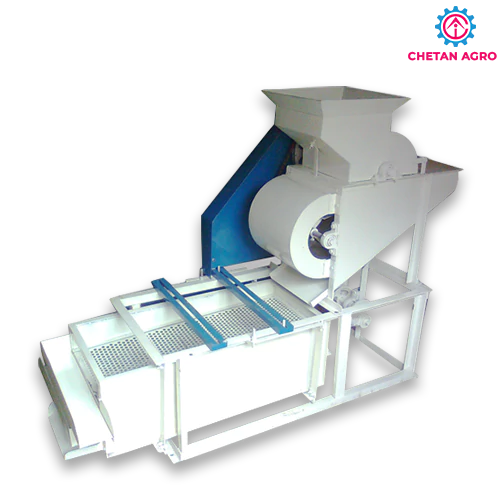

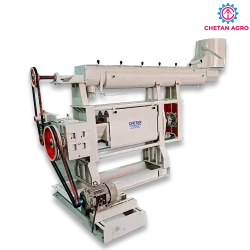

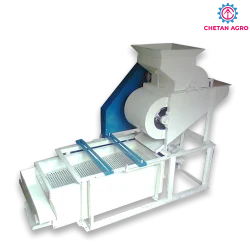

Huller and Shaker (Flat Separator)

kg/hr

hp

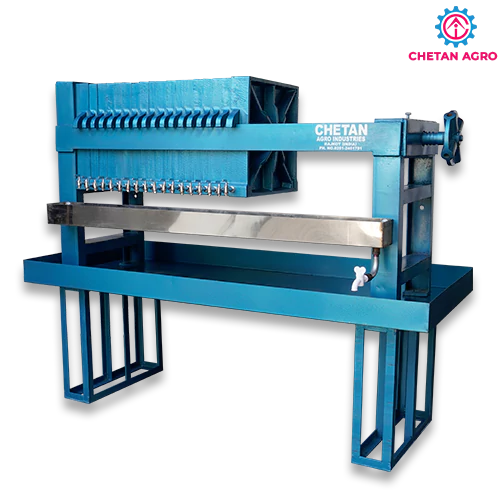

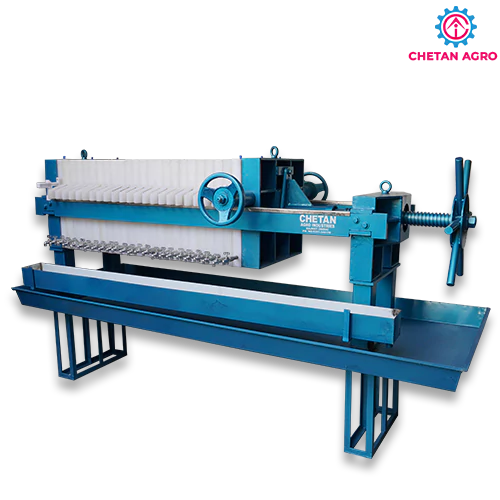

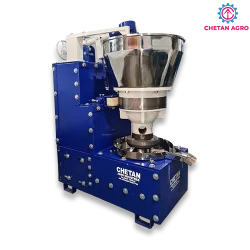

Oil Filtration System

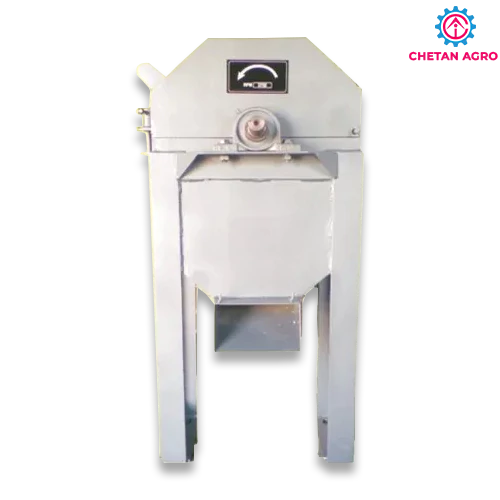

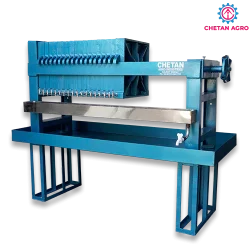

Filter Press Poly Propylene (Plastic)

ltr/hr

hp

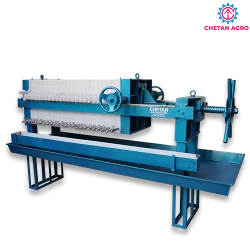

Filter Press CI (Cast Iron)

ltr/hr

hp

ltr/hr

hp

ltr/hr

hp

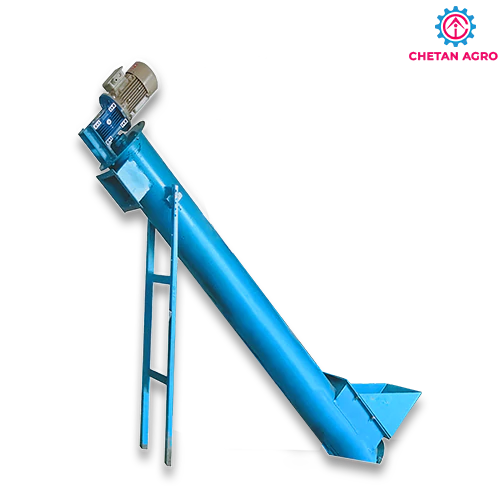

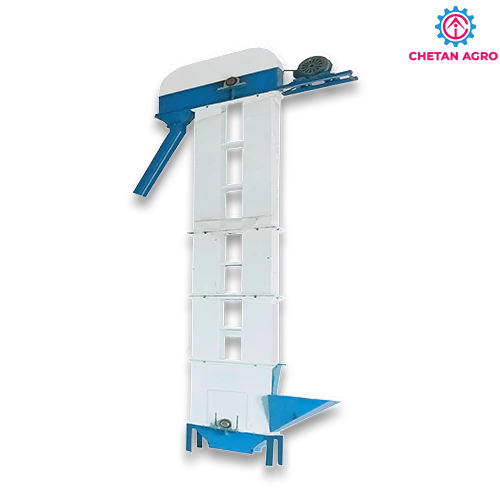

Material Handling Equipment

kg/hr

hp

kg/hr

hp