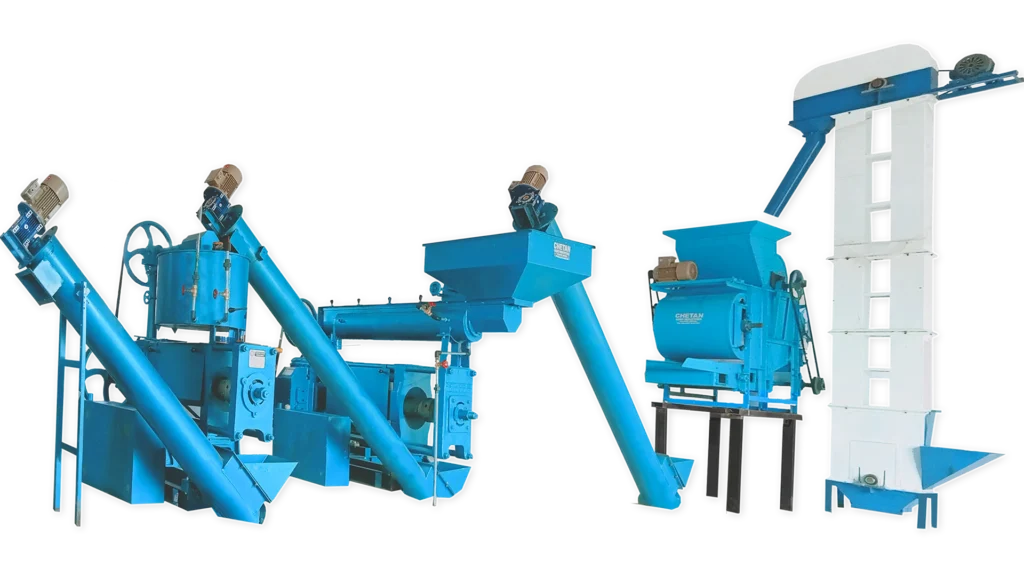

Flaxseed Oil Production Line

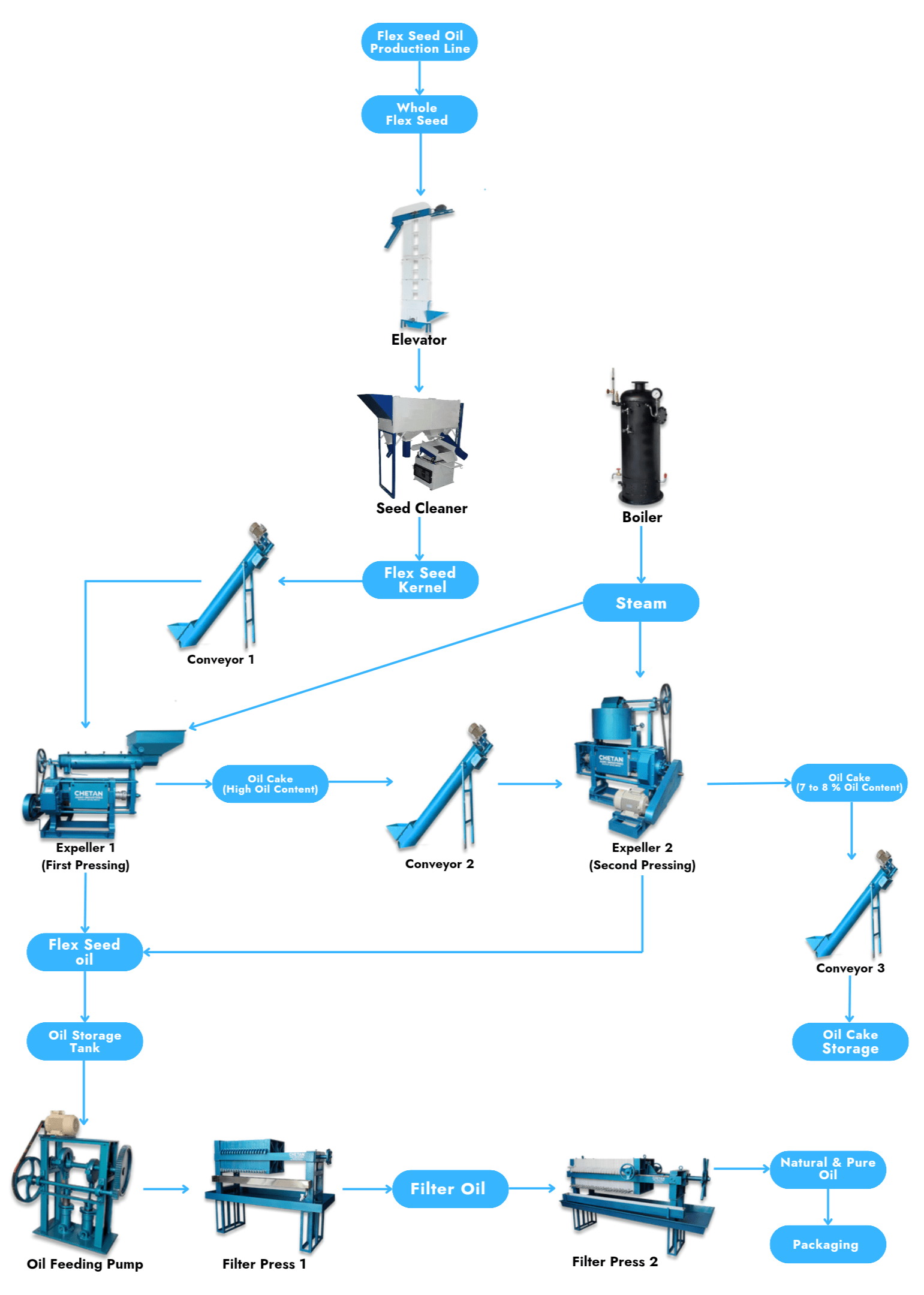

The production of flaxseed oil starts with the harvesting of mature flax seeds from flax plants. The harvested seeds are then cleaned to remove any impurities such as dirt or debris. After cleaning, the seeds are dried to reduce their moisture content, which aids in the extraction process.

Once dried, the seeds are ready for pressing. The pressing process involves using a mechanical expeller to extract the oil from the seeds. The seeds are fed into the expeller, where they are crushed and pressed to release the oil. The oil is then filtered to remove any remaining solids or impurities.

Flaxseed Oil Production Process:

1. Harvesting: Mature flaxseeds are harvested from flax plants.

2. Cleaning: The harvested seeds are cleaned to remove impurities.

3. Drying: The cleaned seeds are dried to reduce moisture content. – Drying can be done using sunlight or a mechanical dryer.

4. Destoning: The dried seeds may undergo a destoning process to remove any stones or heavy materials.

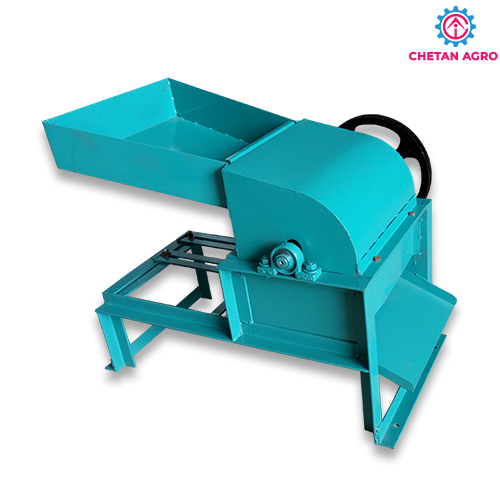

5. Shelling: The flaxseeds may be shelled to separate the outer husk from the inner seed.

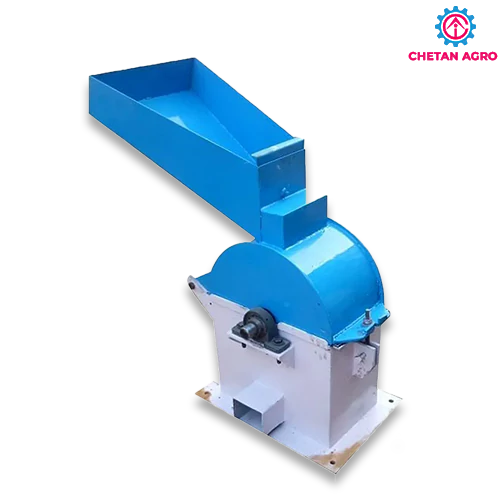

6. Grinding: The shelled or unshelled seeds are ground to a fine powder using a grinder. – Grinding increases the surface area for oil extraction.

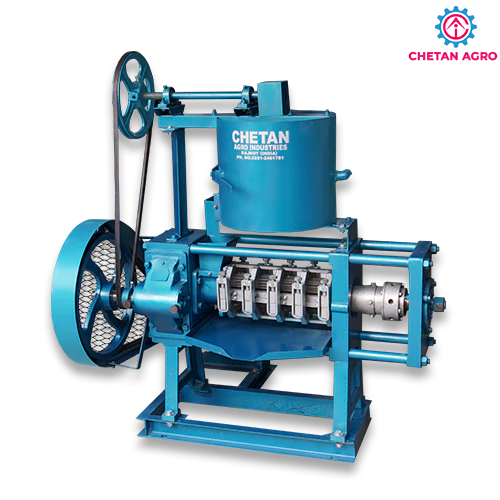

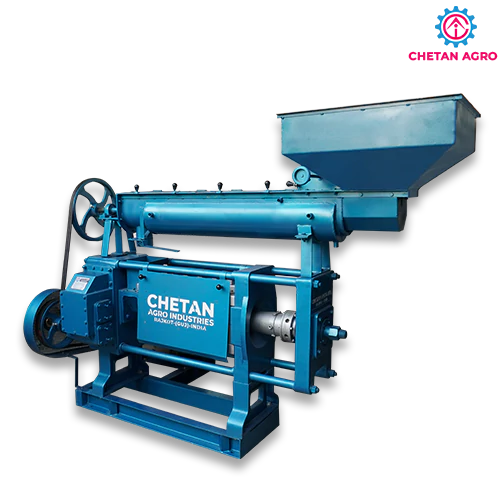

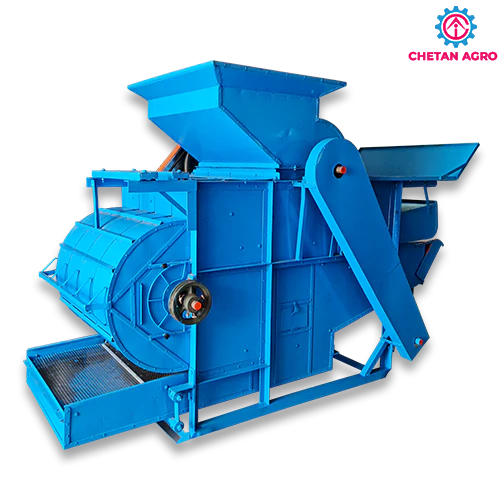

7. Pressing: The ground seeds are pressed using a mechanical expeller to extract the oil. – The expeller applies pressure to the seeds to squeeze out the oil.

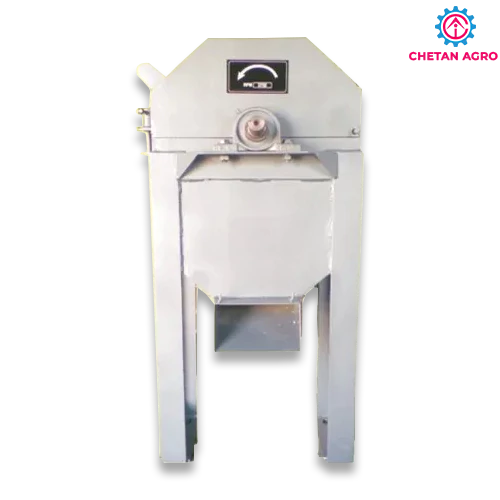

8. Filtering: The extracted oil is filtered to remove any remaining solids or impurities. – Filtration can be done using filter presses or other filtration methods.

9. Settling: The filtered oil is stored in tanks to settle and separate from any water or solids.

10. Clarification: The settled oil may undergo further clarification to remove any remaining impurities.

11. Packaging: The flaxseed oil is packaged into containers for distribution and sale. – Packaging is done according to industry standards and customer requirements.

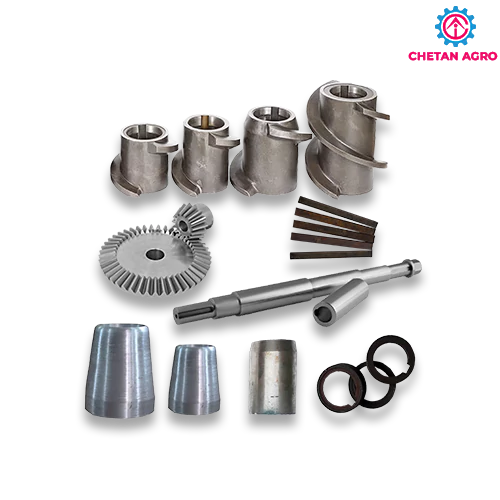

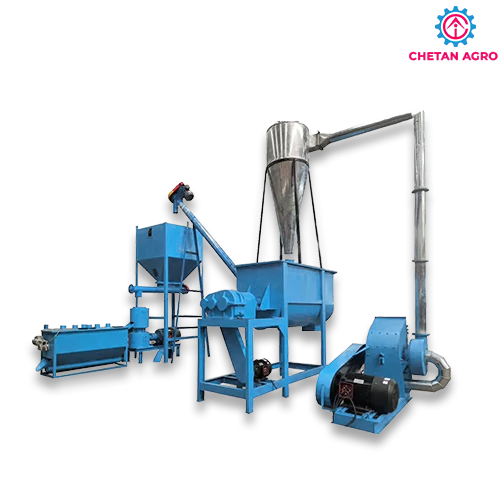

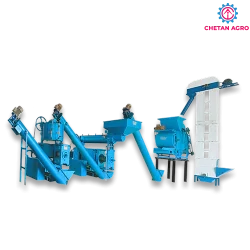

Flaxseed Oil Mill Related Machinery

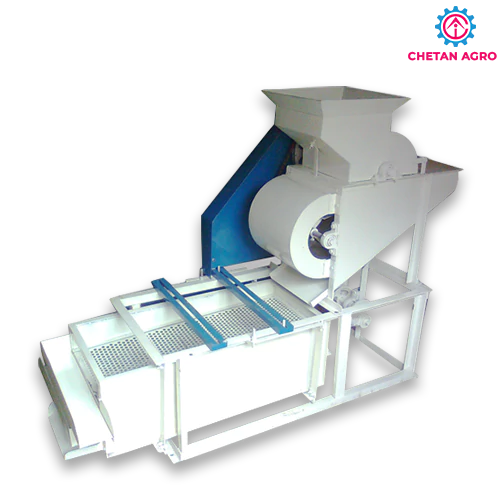

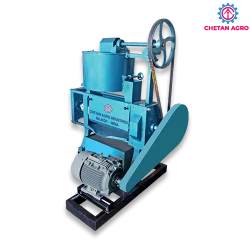

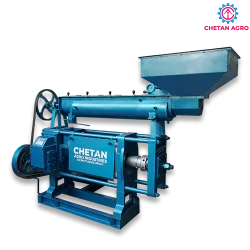

Oil Extraction Machines

6 to 100 TPD Automatic Oil Mill Plant

kg/hr

hp

kg/hr

hp

Mini Oil Mill Plant 2204

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

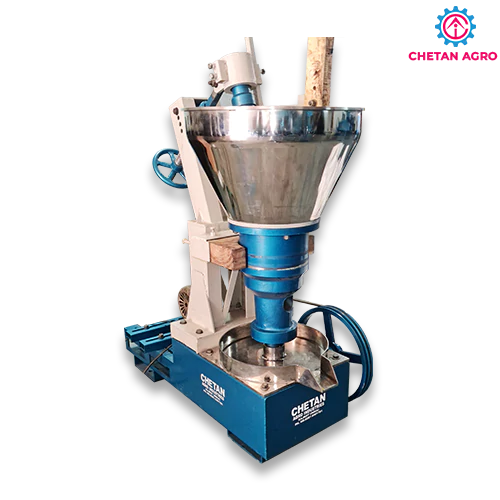

Wooden Oil Press Machine

kg/hr

hp

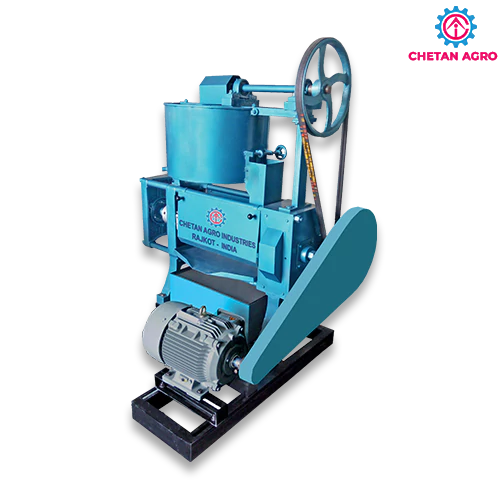

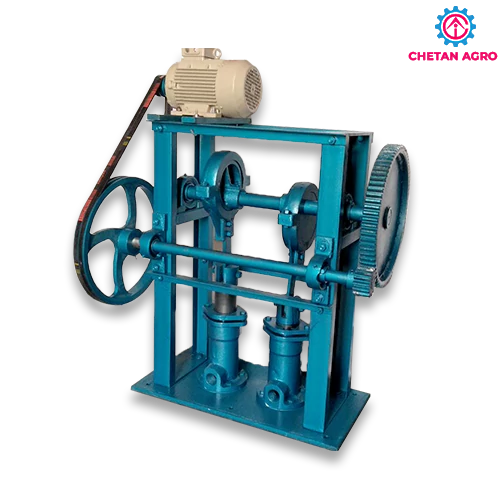

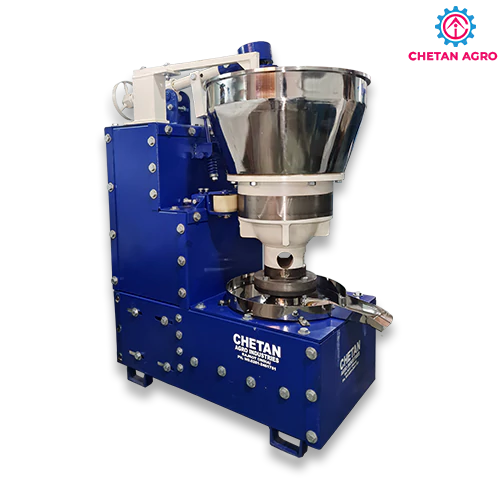

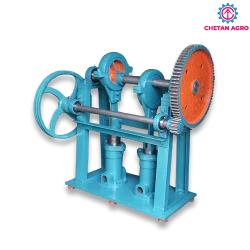

Rotary Oil Ghani Machine

kg/hr

hp

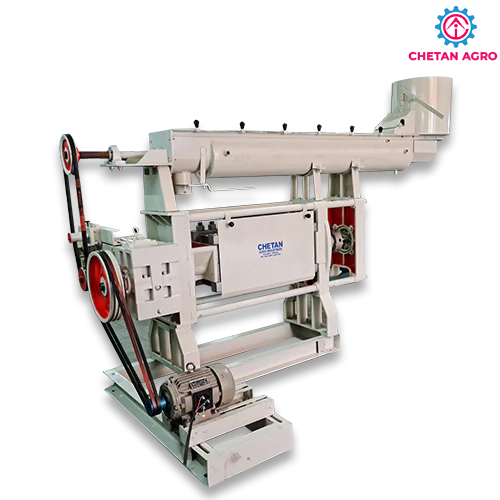

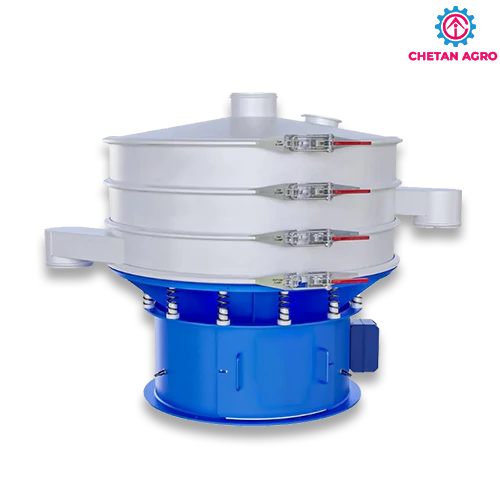

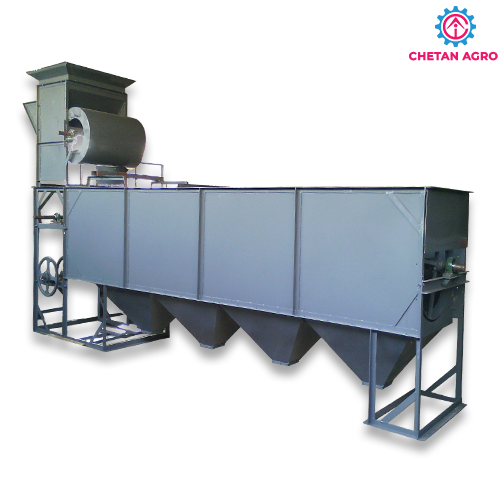

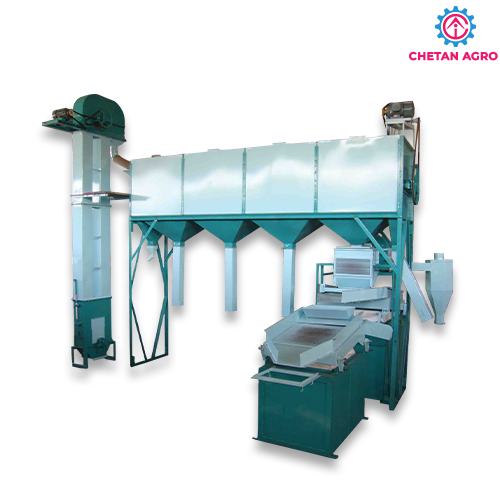

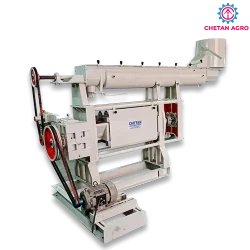

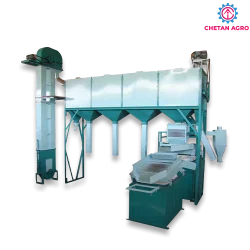

Seed Cleaning and Grading

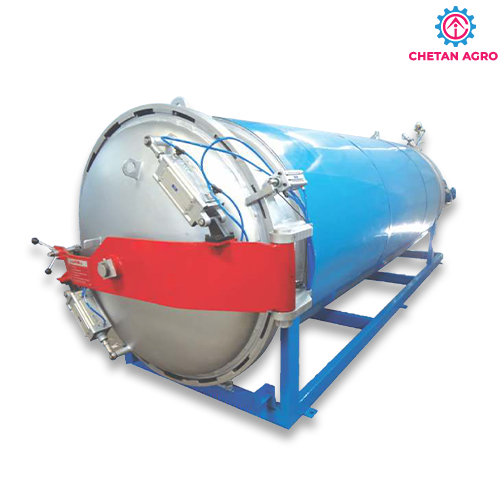

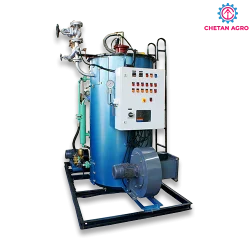

Wood Fire Boiler

kg/hr

hp

kg/hr

hp

Electric Boiler

kg/hr

kw

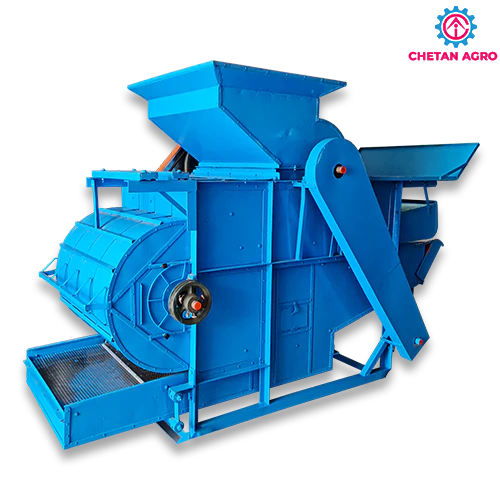

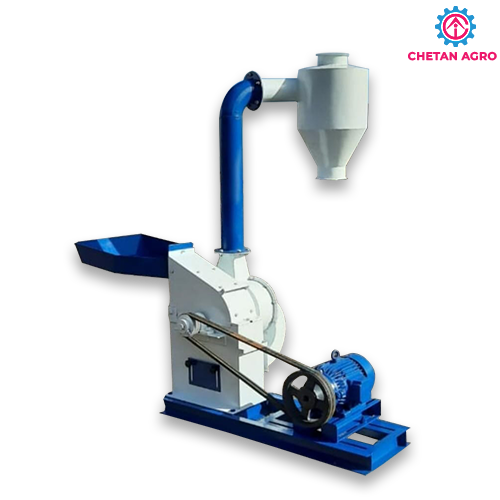

Seed Cleaning Plant

kg/hr

hp

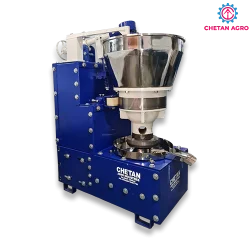

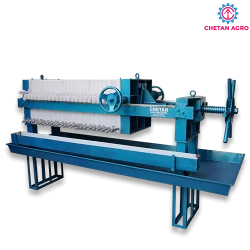

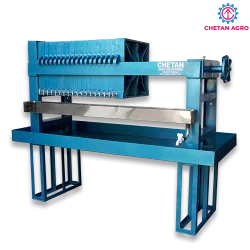

Oil Filtration System

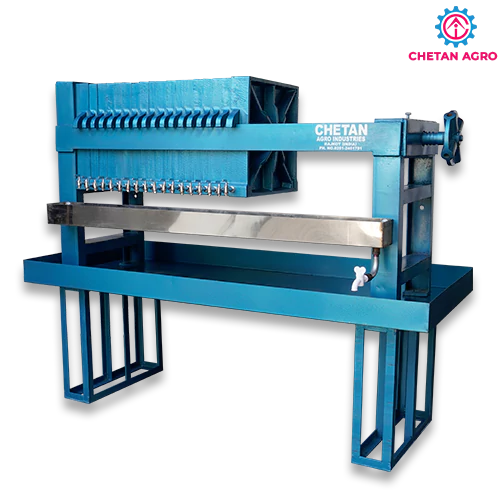

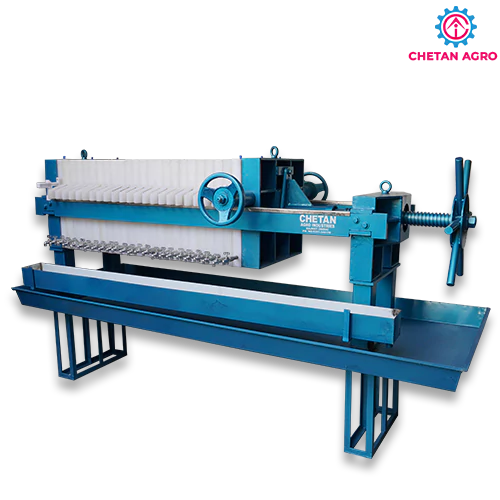

Filter Press Poly Propylene (Plastic)

ltr/hr

hp

Filter Press CI (Cast Iron)

ltr/hr

hp

ltr/hr

hp

ltr/hr

hp

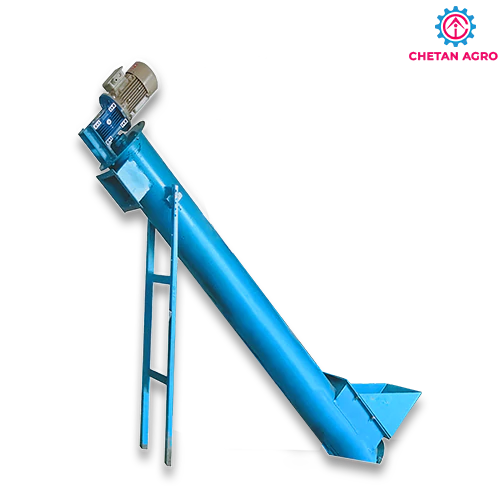

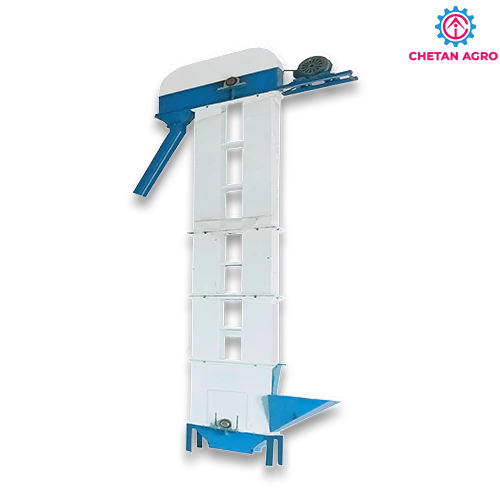

Material Handling Equipment

kg/hr

hp

kg/hr

hp