Palm Kernel Oil Production Line

Palm oil, derived from the fruit of the oil palm tree, is a versatile and widely used vegetable oil in food, cosmetics, and biofuel industries. The production of palm oil involves several key processes, from plantation to oil extraction and refining. The production of palm oil begins with the cultivation of oil palm trees, which are grown in tropical regions with adequate rainfall and sunlight. Once the palm trees mature, typically in 2-3 years, the fruits are harvested and processed to extract the oil. The extracted oil undergoes refining to remove impurities and ensure its quality for use in various applications.

Detailed Process:

- Plantation Establishment:

– Select suitable land for oil palm plantation with well-drained soil and sufficient rainfall.

– Plant oil palm seedlings at recommended spacing and depth.

- Palm Tree Maintenance:

– Provide regular watering and fertilization to promote healthy palm tree growth.

– Control weeds and pests to ensure optimal tree health.

- Fruit Harvesting:

– Harvest the palm fruits once they are mature and have turned red.

– Use tools such as sickles or harvesting poles to cut the fruit bunches.

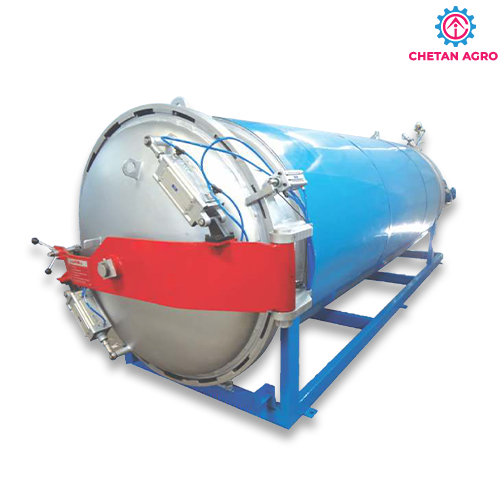

- Fruit Sterilization:

– Sterilize the harvested palm fruits to deactivate enzymes and facilitate oil extraction.

– Use steam or hot water for sterilization.

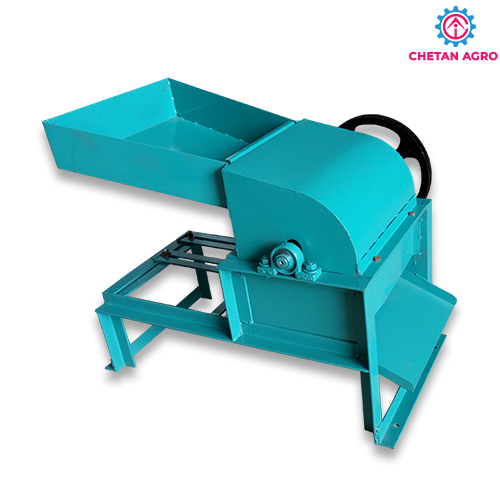

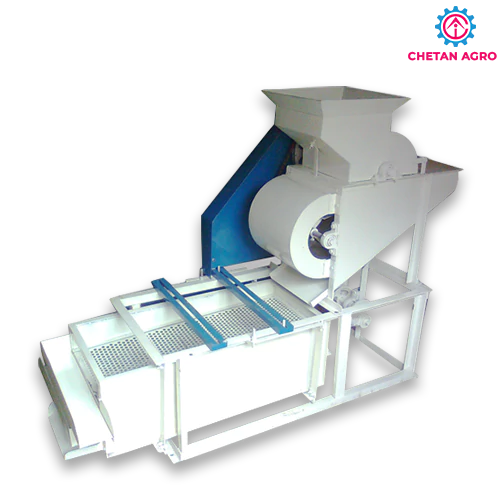

- Fruit Threshing:

– Separate the palm fruits from the bunches using a mechanical thresher.

– Collect the fruits for further processing.

- Fruit Digestion:

– Digest the separated palm fruits to loosen the pulp.

– Use a digester or similar equipment for this process.

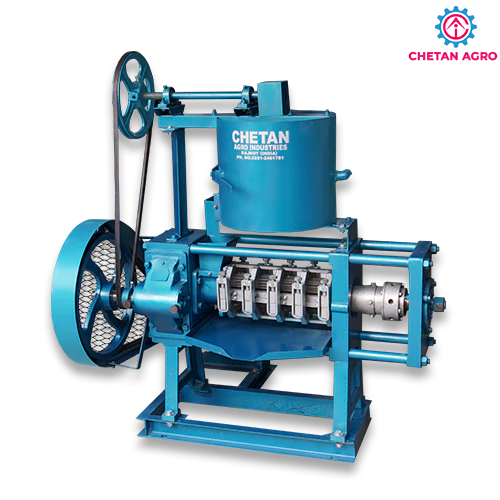

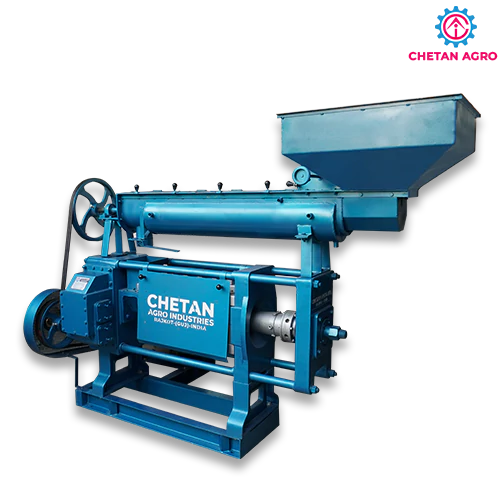

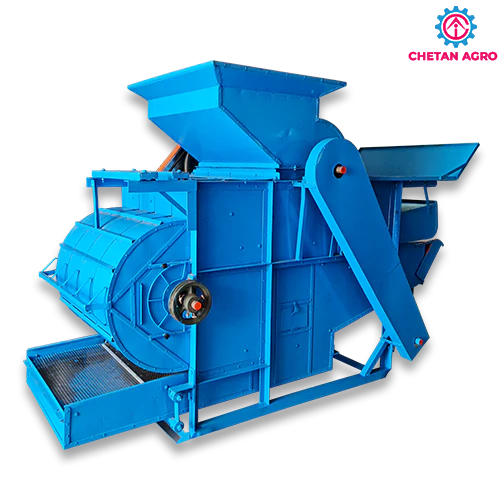

- Oil Extraction:

– Extract the oil from the digested palm fruits.

– Use a mechanical press or solvent extraction method.

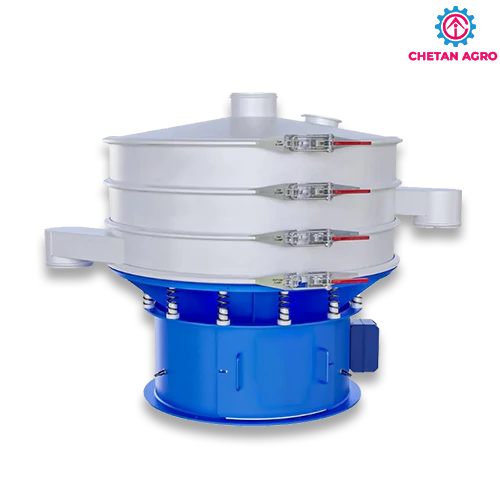

- Oil Clarification:

– Clarify the extracted oil to remove impurities and water.

– Use processes such as settling, centrifugation, or filtration.

- Oil Refining:

– Refine the clarified oil to improve its quality.

– Use processes such as degumming, neutralization, bleaching, and deodorization.

- Oil Fractionation (Optional):

– Fractionate the refined oil to separate it into different fractions with different melting points.

– Use processes such as crystallization and filtration.

- Quality Control:

– Conduct regular quality checks on the palm oil to ensure it meets standards.

– Monitor the production process for consistency and quality control.

- Packaging and Distribution:

– Package the refined palm oil in suitable containers for distribution.

– Label the containers with relevant information, such as batch number and expiry date.

The production of palm oil requires careful planning and sustainable practices to ensure environmental and social responsibility. By following the above steps, producers can extract and refine palm oil efficiently for various applications while minimizing environmental impact.

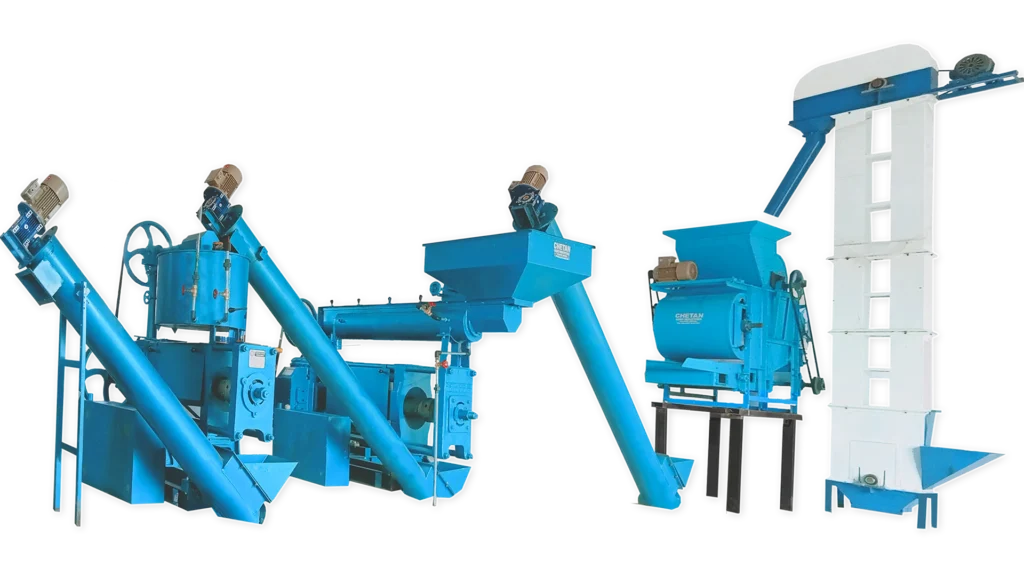

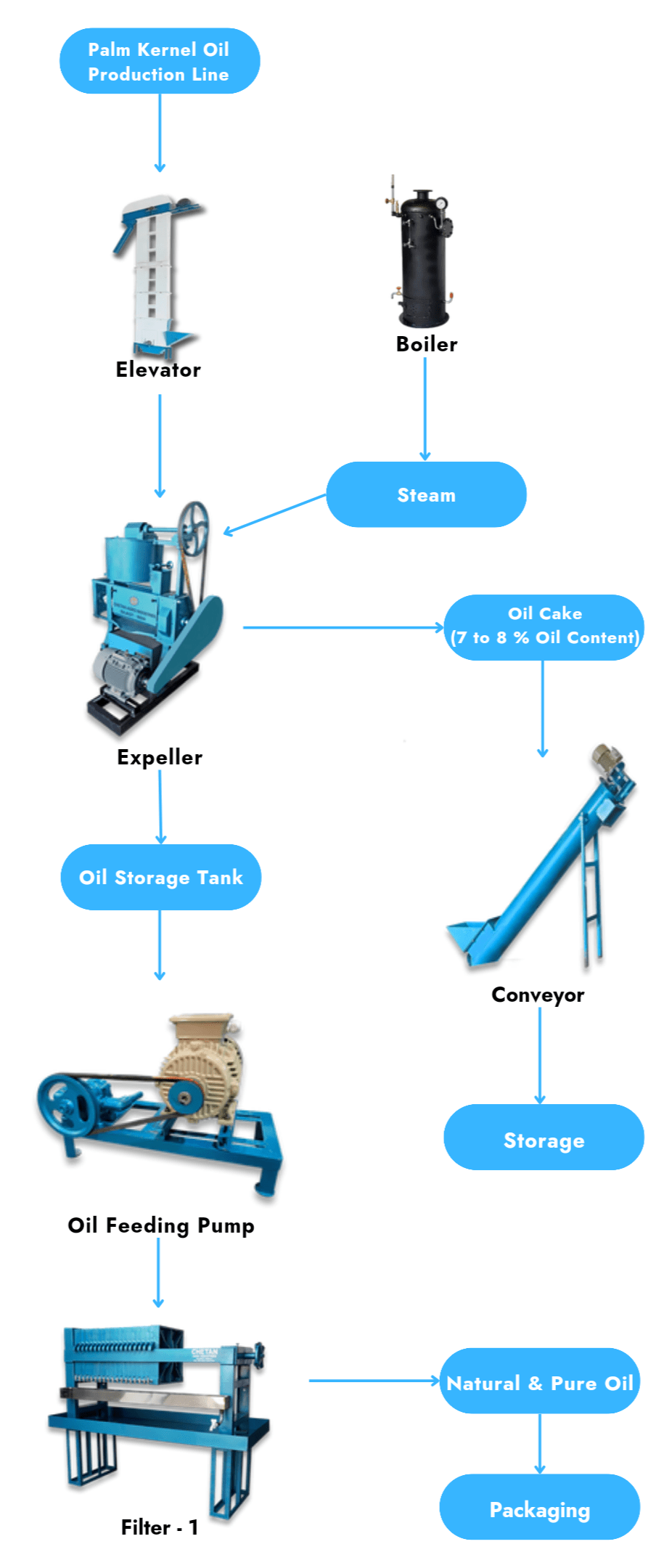

Comprehensive Flowchart: Palm Kernel Processing

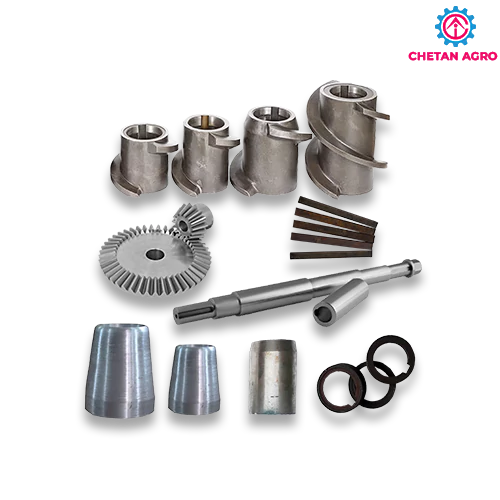

Palm Oil Extraction Machinery Catalog: Explore Our Range

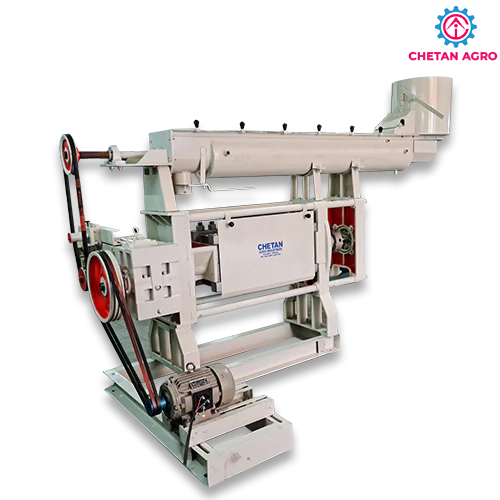

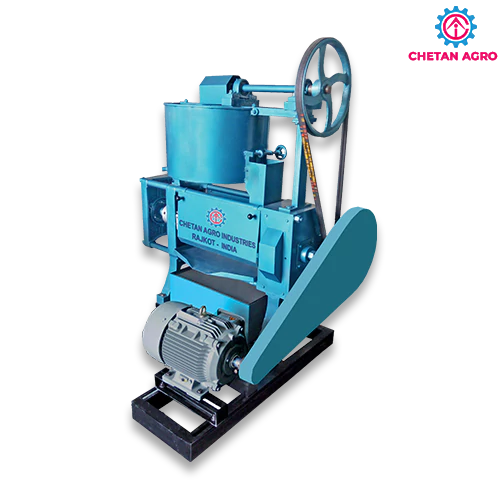

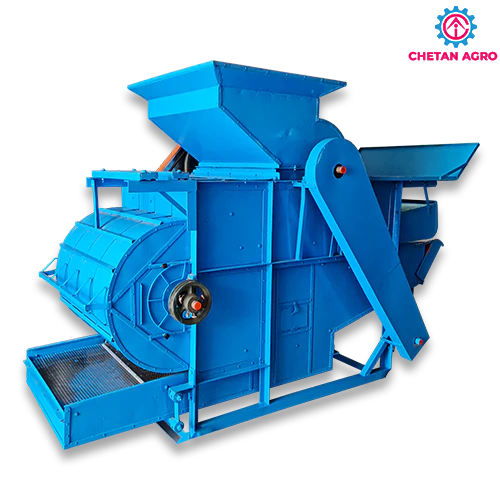

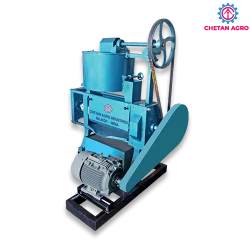

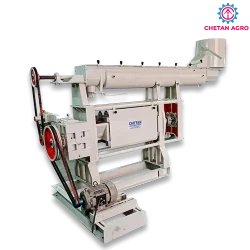

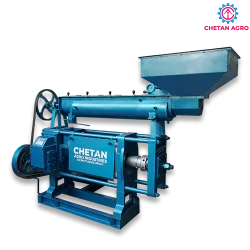

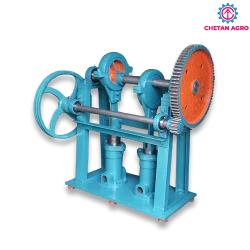

Oil Extraction Machines

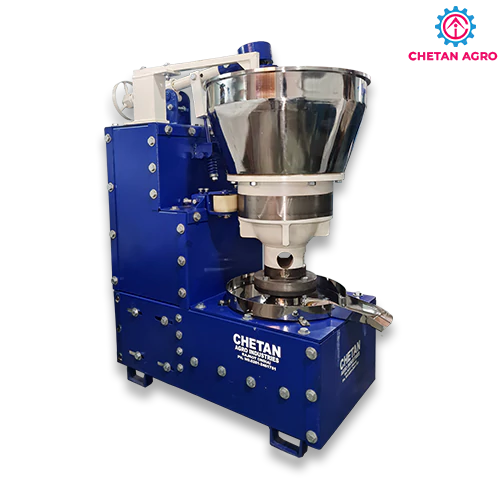

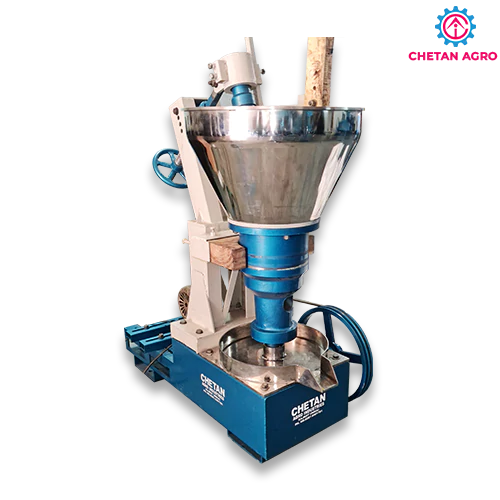

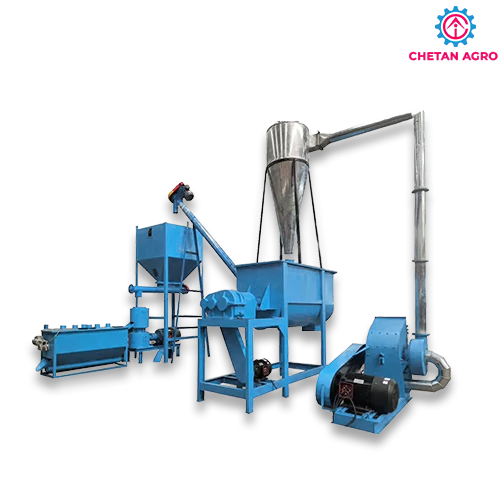

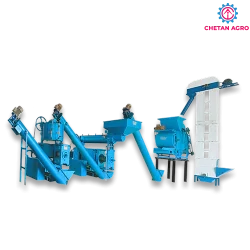

6 to 100 TPD Automatic Oil Mill Plant

kg/hr

hp

kg/hr

hp

Mini Oil Mill Plant 2204

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

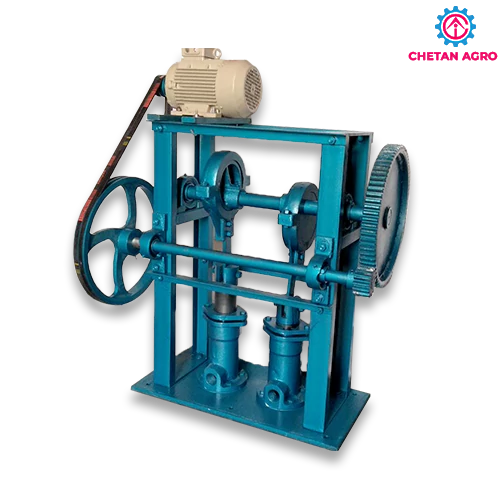

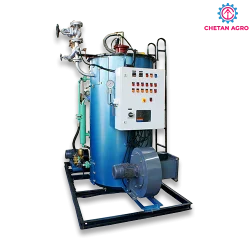

Boiler For Oil Extraction

Wood Fire Boiler

kg/hr

hp

kg/hr

hp

Electric Boiler

kg/hr

kw

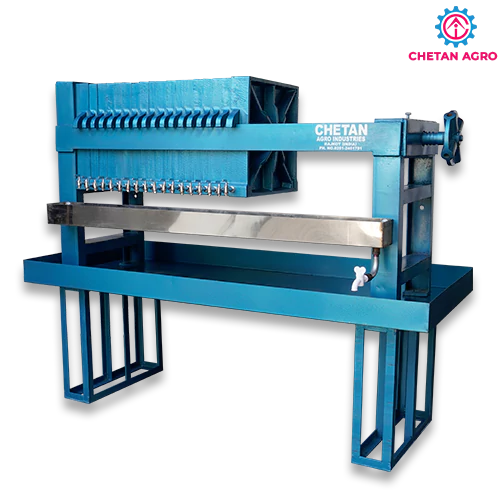

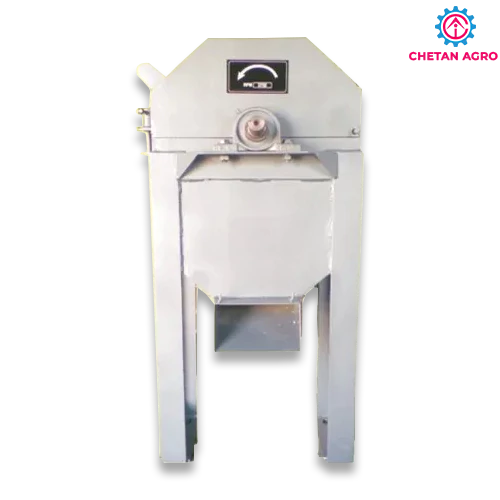

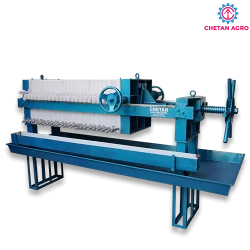

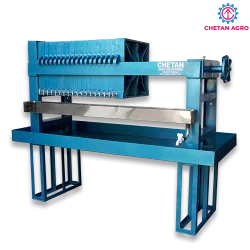

Oil Filtration System

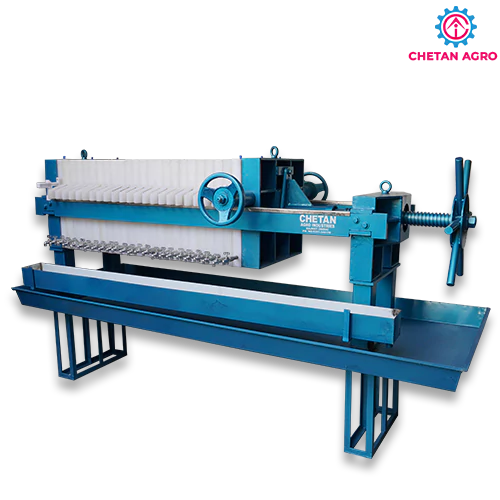

Filter Press Poly Propylene (Plastic)

ltr/hr

hp

Filter Press CI (Cast Iron)

ltr/hr

hp

ltr/hr

hp

ltr/hr

hp

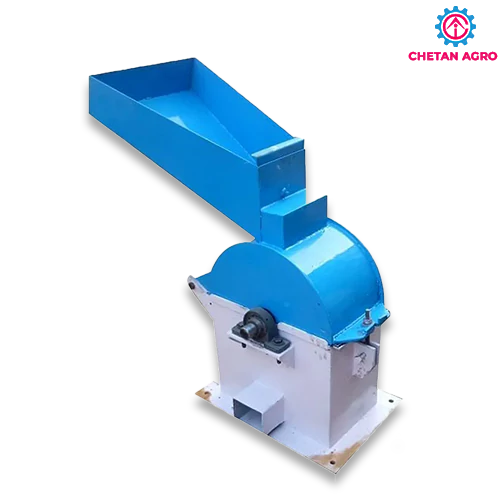

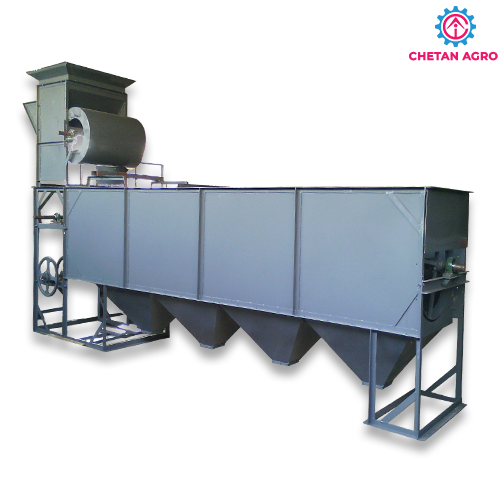

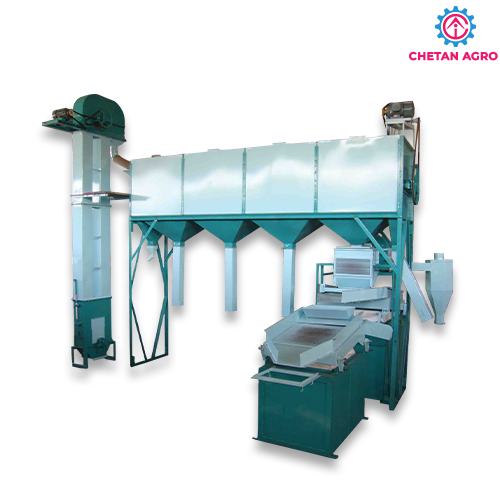

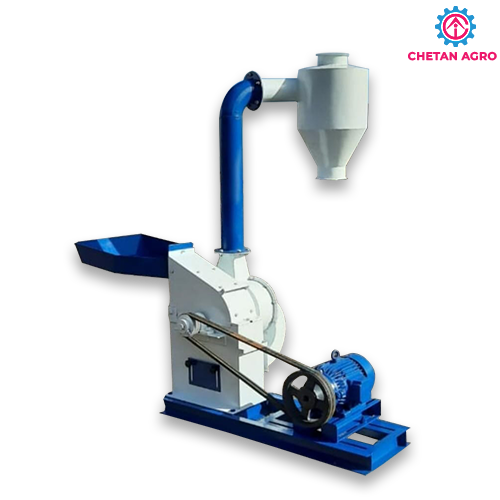

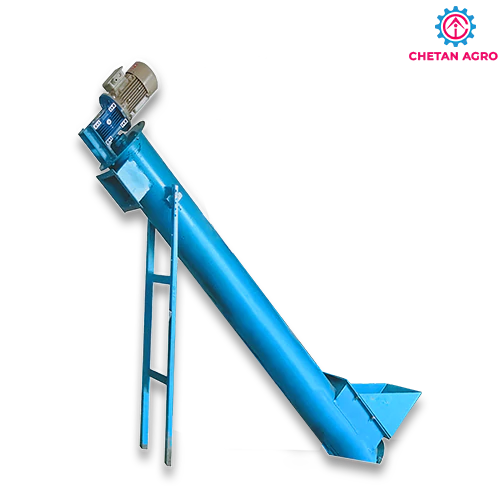

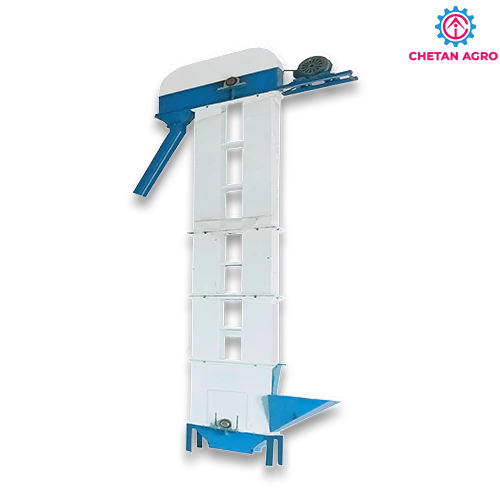

Material Handling Equipment

kg/hr

hp

kg/hr

hp