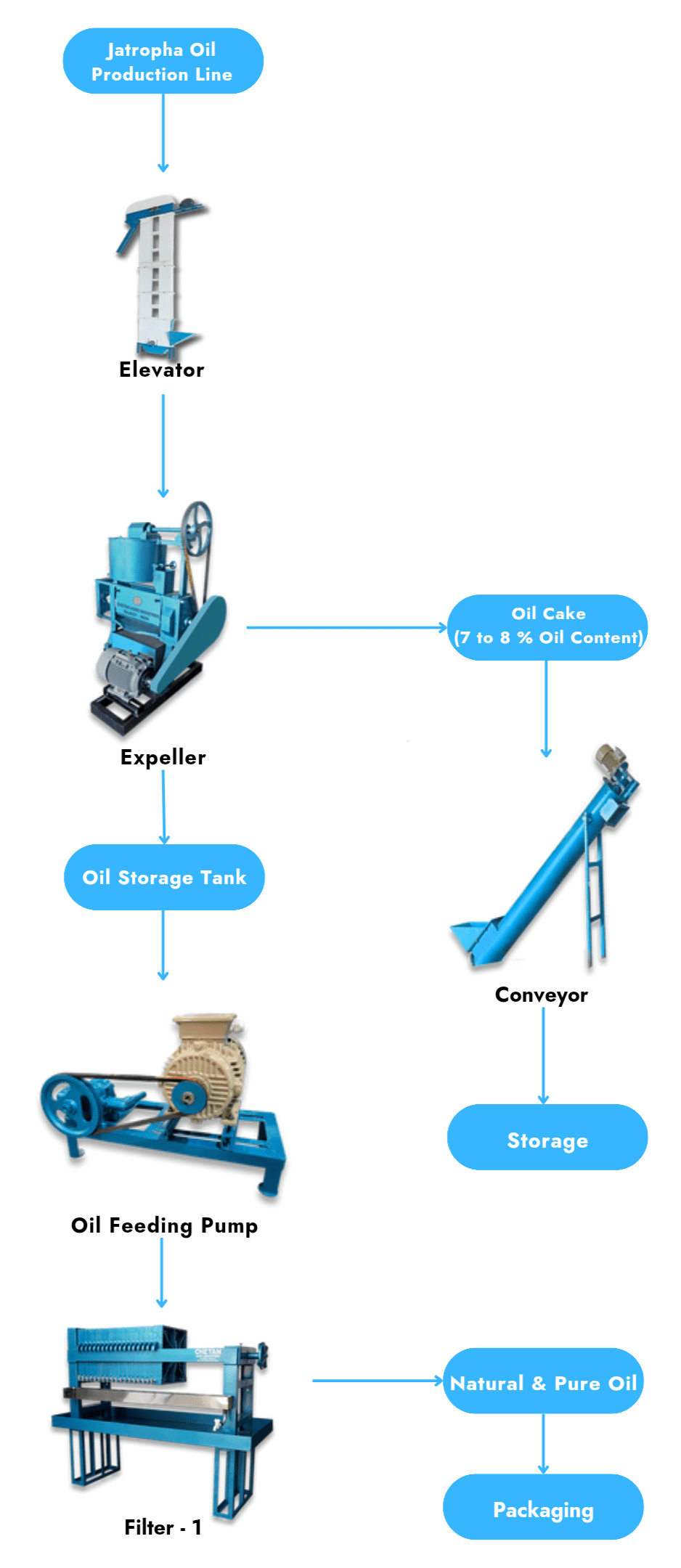

Jatropha Oil Production Process Overview.

Jatropha oil, derived from the seeds of the Jatropha plant, is a valuable biofuel and feedstock for various industrial applications. The production of Jatropha oil involves several key processes, from seed cultivation to oil extraction and refining. Here is an overview of the Jatropha oil production line, followed by detailed steps: The production of Jatropha oil begins with the cultivation of Jatropha plants, which are grown in suitable climates with well-drained soils. Once the plants reach maturity, typically in 2-3 years, the seeds are harvested and processed to extract the oil. The extracted oil is then refined to remove impurities and ensure its quality for use in biodiesel production, cosmetics, and other applications.

1. Seed Selection and Cultivation:

– Select high-quality Jatropha seeds for cultivation.

– Prepare the land with well-drained soil and adequate sunlight.

– Plant the seeds at the recommended spacing and depth.

2. Seed Germination and Plant Growth:

– Water the seeds regularly to promote germination.

– Provide appropriate nutrients and care for healthy plant growth.

3. Seed Harvesting:

– Harvest the Jatropha seeds once the fruits are mature and dry.

– Collect the seeds in a clean container to prevent contamination.

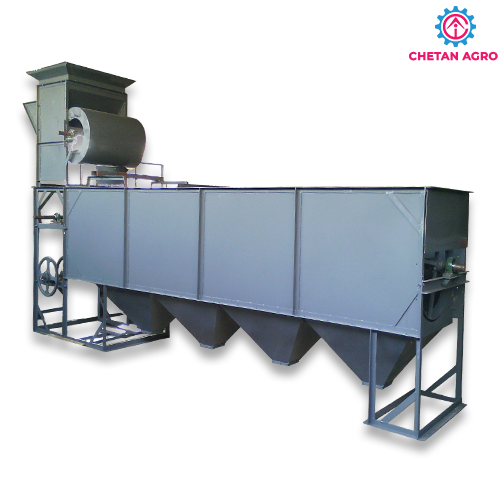

4. Seed Cleaning:

– Remove any debris or impurities from the harvested seeds.

– Clean the seeds using water or a suitable cleaning process.

5. Seed Drying:

– Dry the cleaned seeds to reduce moisture content.

– Use a drying machine or natural drying methods.

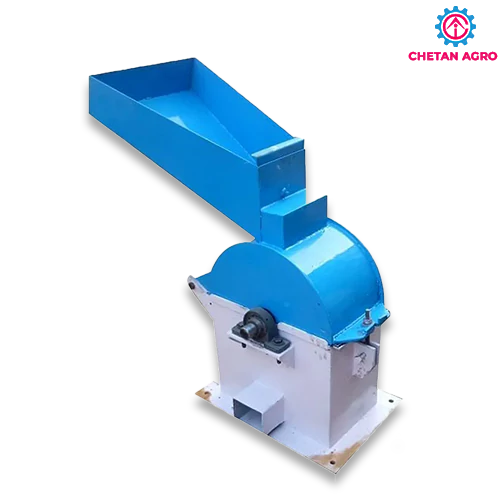

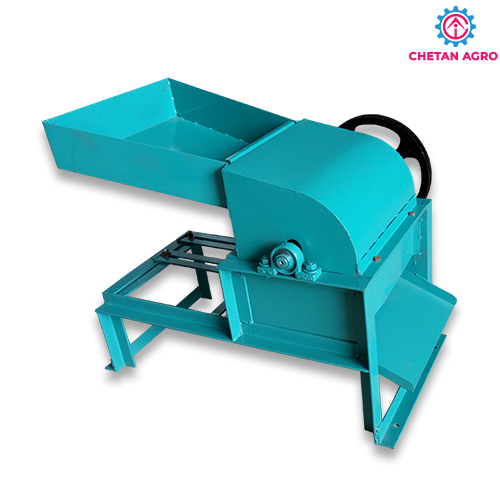

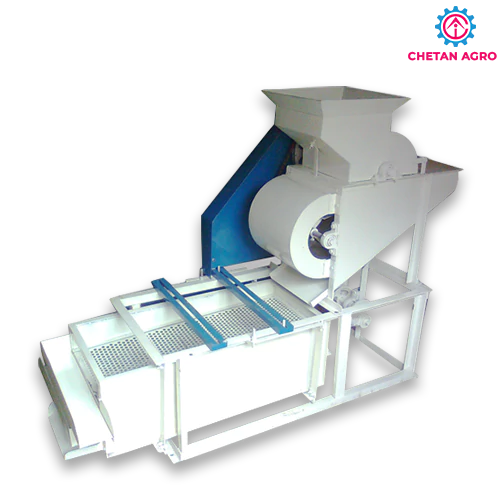

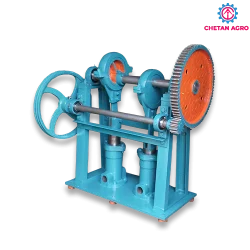

6. Seed Crushing:

– Crush the dried Jatropha seeds to extract the oil.

– Use a mechanical press or solvent extraction method.

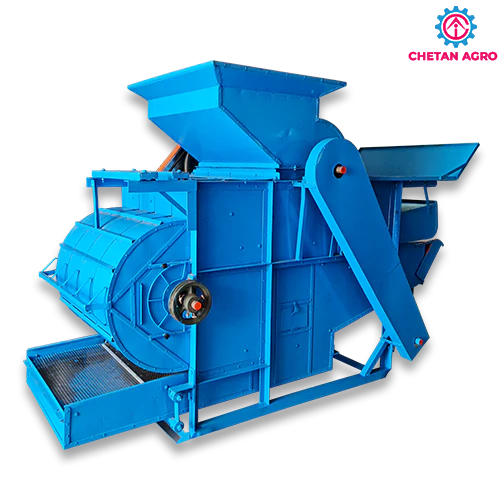

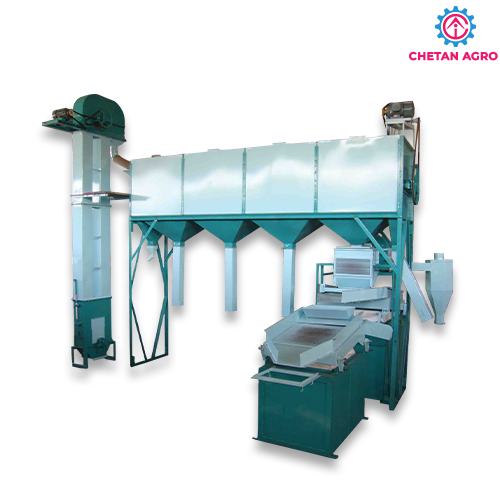

7. Oil Extraction:

– Separate the oil from the crushed seeds using a suitable extraction process.

– Use mechanical pressing, solvent extraction, or other methods.

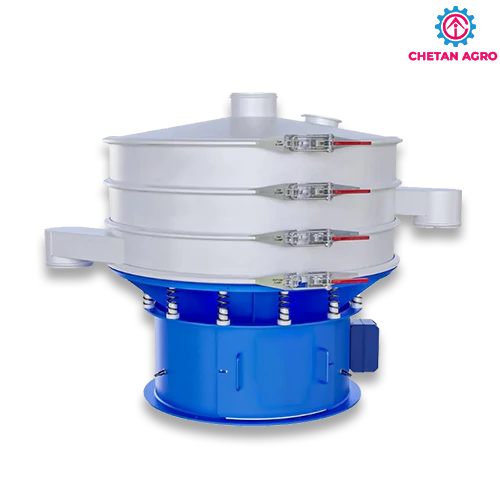

8. Oil Filtration:

– Filter the extracted oil to remove any remaining impurities.

– Use filters or other suitable filtration methods.

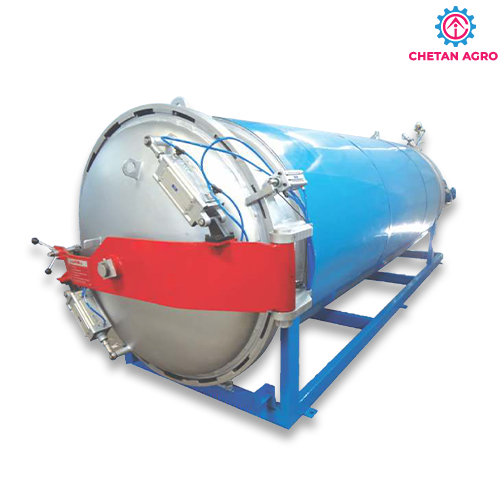

9. Oil Refining:

– Refine the filtered oil to improve its quality.

– Use processes such as degumming, neutralization, and bleaching.

10. Oil Storage:

– Store the refined Jatropha oil in clean, airtight containers.

– Protect the oil from light, heat, and oxygen to maintain its quality.

11. By-Product Utilization:

– Use the by-products of Jatropha oil production, such as seed cake, for various purposes.

– The seed cake can be used as a fertilizer or animal feed.

12. Quality Control:

– Conduct regular quality checks on the Jatropha oil to ensure it meets standards.

– Monitor the production process for consistency and quality control.

13. Packaging and Distribution:

– Package the refined Jatropha oil in suitable containers for distribution.

– Label the containers with relevant information, such as batch number and expiry date.

The production of Jatropha oil requires careful planning and management to ensure a high-quality product. By following the above steps, producers can extract and refine Jatropha oil efficiently for use in various industries.

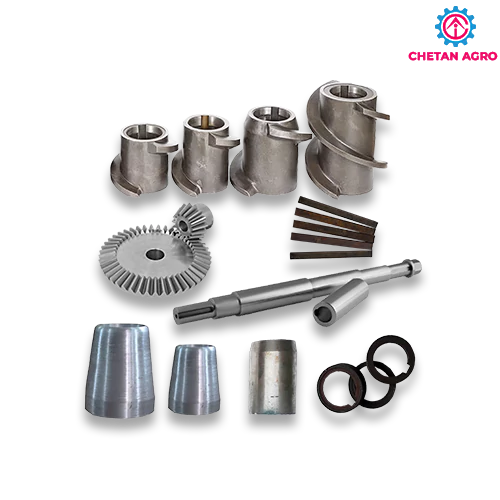

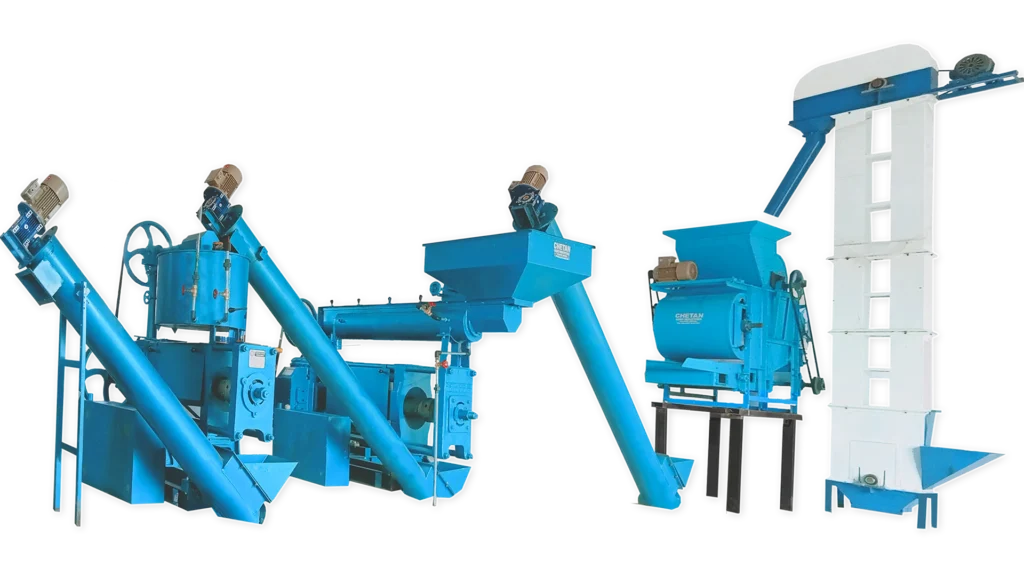

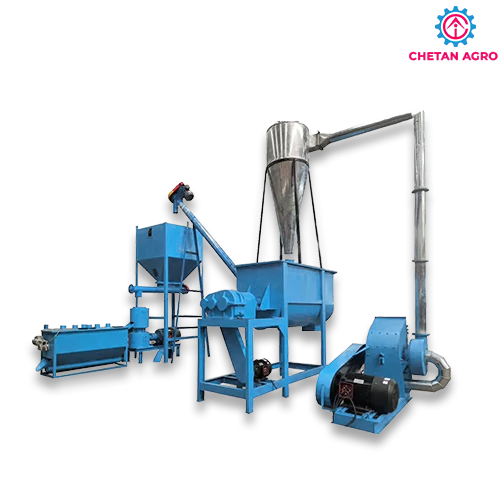

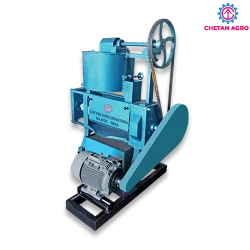

Jatropha Oil Extraction Related Machinery

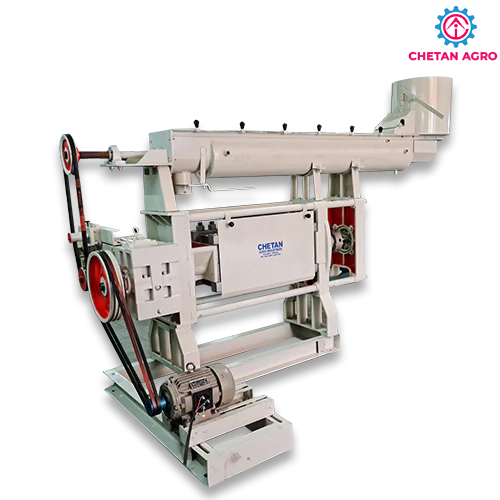

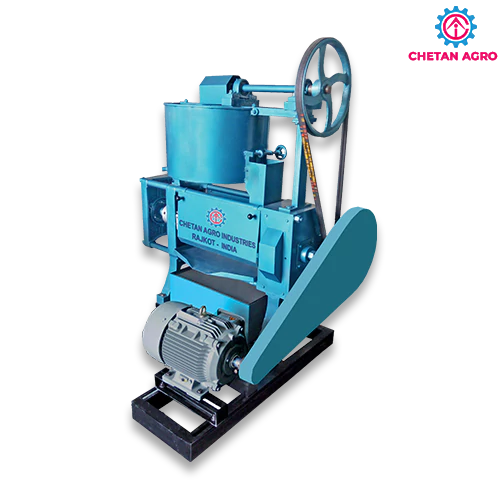

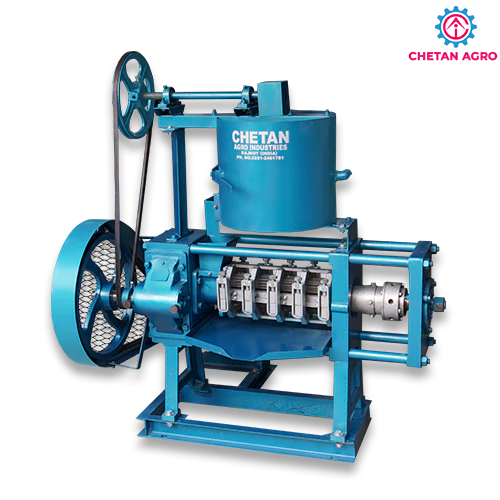

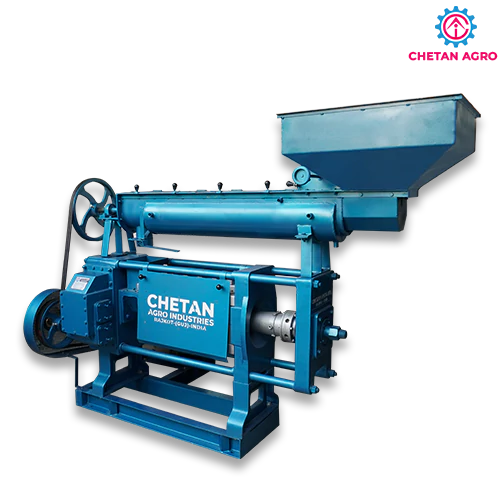

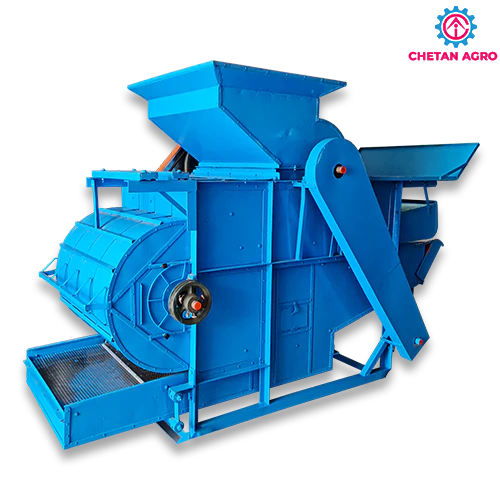

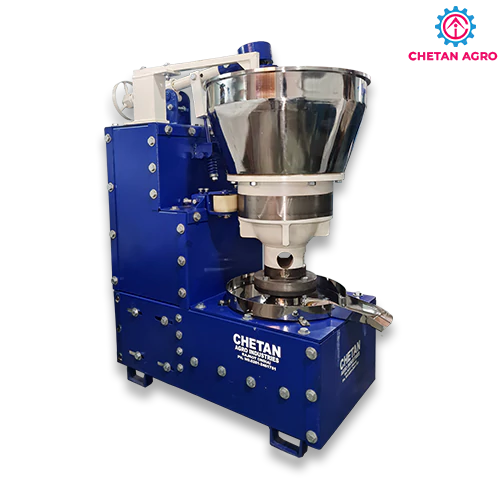

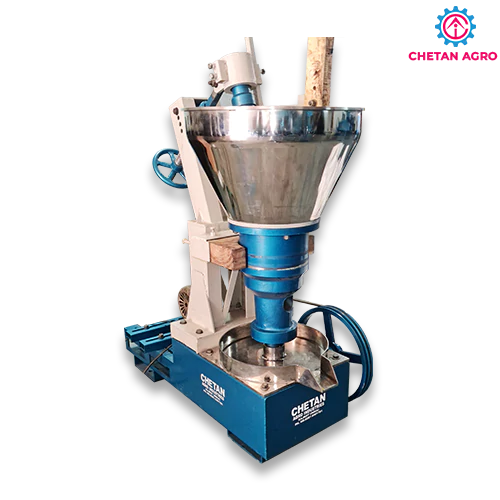

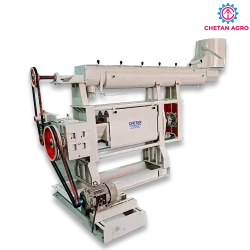

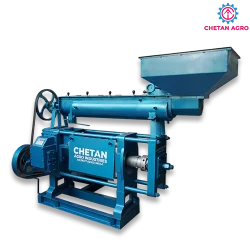

Oil Extraction Machines

6 to 100 TPD Automatic Oil Mill Plant

kg/hr

hp

kg/hr

hp

Mini Oil Mill Plant 2204

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

kg/hr

hp

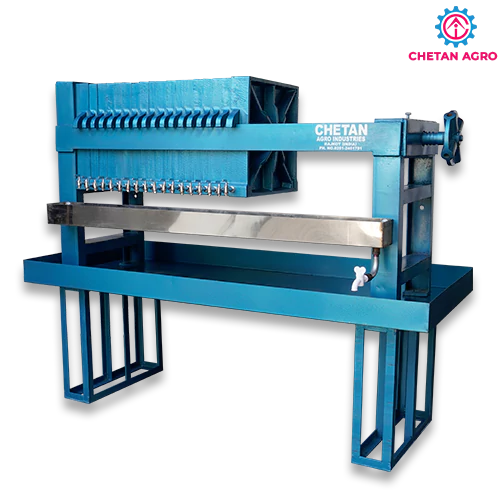

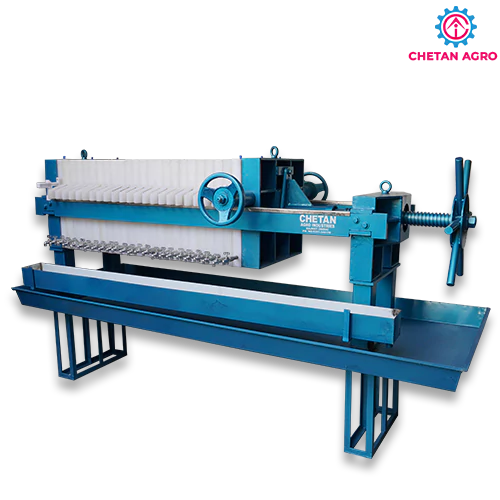

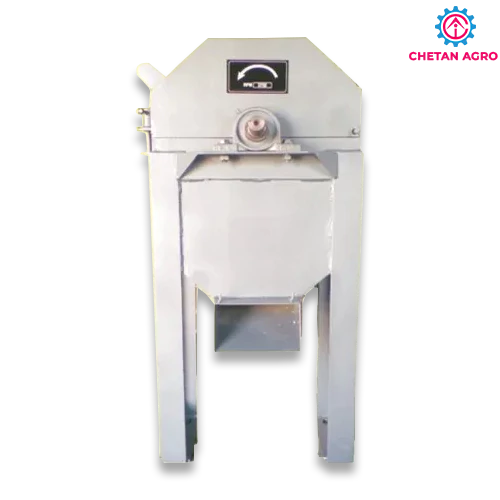

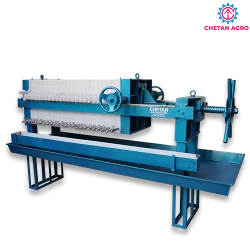

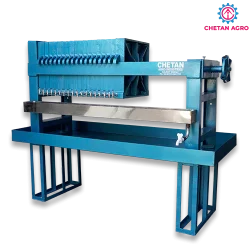

Oil Filtration System

Filter Press Poly Propylene (Plastic)

ltr/hr

hp

Filter Press CI (Cast Iron)

ltr/hr

hp

ltr/hr

hp

ltr/hr

hp

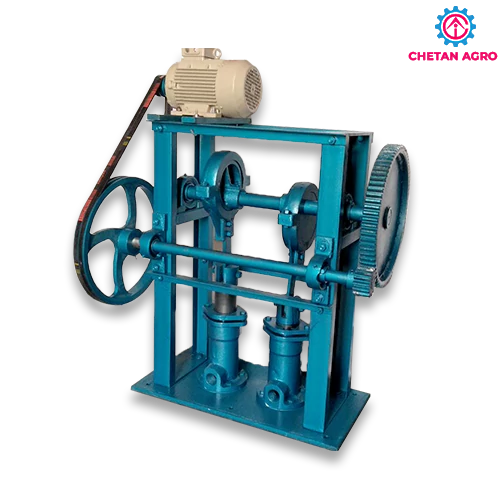

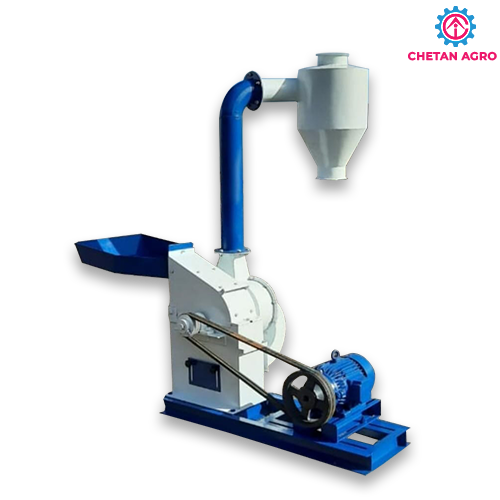

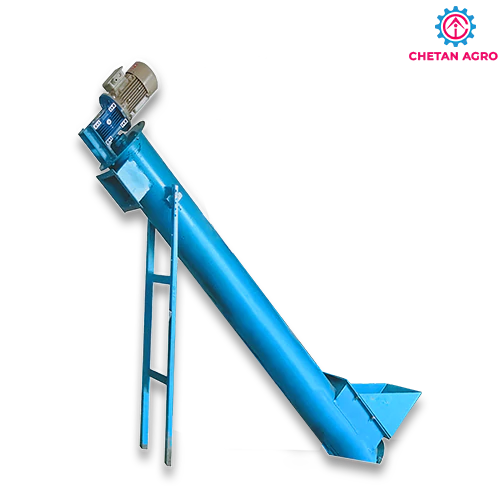

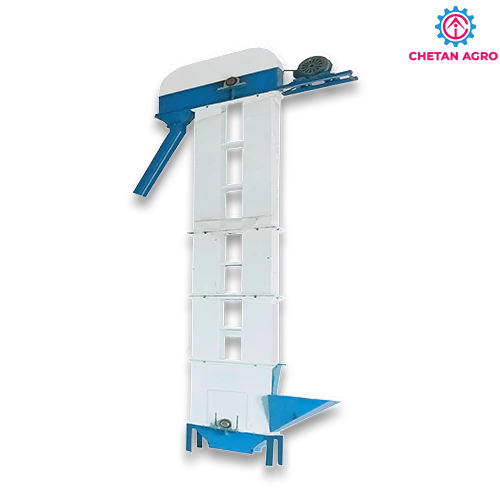

Material Handling Equipment

kg/hr

hp

kg/hr

hp